1600T

Wide-Area Mower

- Powerful 4-cylinder turbocharged diesel engine

- Mechanical rear-wheel drive

- Maximum speed of 23 km/h

- Foldable mowing wings

Features

Powerful turbocharged diesel engine for superior performance

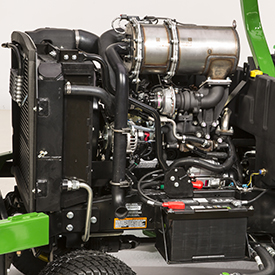

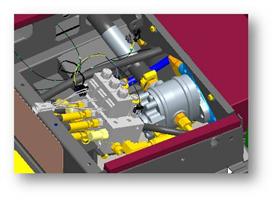

1600 Turbo TerrainCut™ Wide-Area Mower (WAM) engine

1600 Turbo TerrainCut™ Wide-Area Mower (WAM) engine  1600 Turbo TerrainCut WAM engine

1600 Turbo TerrainCut WAM engine The 1600 Turbo TerrainCut WAM is powered by a liquid-cooled, turbocharged, four-cylinder, 44.7 kW (60 hp) at 3000 rpm, diesel engine.

Engine features include:

- 159 Nm (117.3 lb-ft) of torque at 3000 rpm for extra lugging power on hills and in tough mowing conditions

- Large 2.091 L (127.6 cu in.) displacement, which produces the torque needed to handle hills and tough mowing conditions

Engine is a 16-valve (four valves per cylinder, two intake and two exhaust) design:

- Cold-start device to increase engine timing for improved cold starting

- Full-pressure lubrication for positive lubrication with continuous operation on slopes

- Dual-element air filter that is completely sealed for effective cleaning

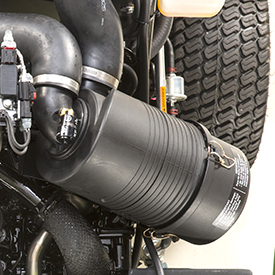

Air filter with air-restriction indicator

Air filter with air-restriction indicator  Air-restriction indicator

Air-restriction indicator - Progressive-type air-restriction indicator to let operator know when the filter needs servicing

- Automotive-type alternator (75 amp) that provides plenty of charge to the battery

- Glow plugs for quick starting in cold weather

- Automotive sensing system, which tells the operator when the engine is ready to start

- Isolated engine mounting, which reduces engine vibration in the operator's station for more comfortable operation

Direct fuel injection

- Injects fuel directly on top of pistons for more efficient combustion, less emissions

- Delivers more power per gallon of fuel

- Quicker starting and quieter operation

- Designed to meet California emission standards

- Features low levels of exhaust and emissions and excellent fuel economy. It meets the necessary Environmental Protection Agency (EPA) Tier 4 standard and meets 97/68/EC EU non-road mobile machinery (NRMM) emissions regulation

- Electronic engine control and cooled exhaust gas recirculation (EGR) system

- High-pressure common fuel rail for lower emissions and improved engine responsiveness

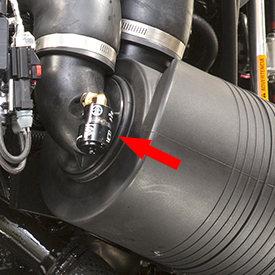

Flow of exhaust during engine operation

- Exhaust airflow enters into the EGR cooler from the exhaust manifold near the turbocharger

- Cooler takes hot exhaust gases and cools them to where the temperature will not have excessive impact on combustion efficiency

- Based on load, air temperatures, and rpm, the engine control unit (ECU) opens (or closes) the EGR valve, allowing exhaust gases into the intake manifold. The gases mix with the rest of the incoming air from the turbocharger and aftercooler.

Other engine features:

- Overhead valve (OHV) for efficient combustion

- Liquid-cooled for more consistent operating temperatures

- Closed crankcase ventilation that burns crankcase hydro-carbon evaporation

1600 Turbo TerrainCut WAM side view

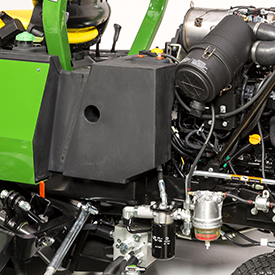

1600 Turbo TerrainCut WAM side view  Deluxe air-intake system

Deluxe air-intake system - Deluxe air-intake system

- Hood that is composed of a large, black, cross-link polyethylene-composite center section with green, metal side panels

- The composite center section includes air-intake screens and helps to guide the cooler air from above the machine to the radiator. The design provides a uniform distribution of clean air, as well as minimizing the amount of chaff collection on the exterior screens.

- Additional sealing around the operator station reduces the amount of hot air blowing on the operator, which in turn improves operator comfort.

- The rear bumper helps with hood sealing and reduces the potential for rear hood damage.

83.3 L (22 gal.) of fuel on board, plenty for a long day of mowing

Fuel tank

Fuel tank  Large fuel fill opening

Large fuel fill opening The operator can fill the fuel tank without removing the hood. The fuel tank capacity is 83.3 L (22 U.S. gal.) for all-day mowing.

Exclusive air-intake system draws clean air from the top of the machine for consistent cooling

Air-intake system

Air-intake system  High-capacity cooling system

High-capacity cooling system An innovative, exclusive air-intake system draws clean air from the top of the machine instead of the rear. This keeps the radiator cleaner and prevents the engine from overheating.

The high-capacity cooling system combines the radiator and hydraulic oil cooler.

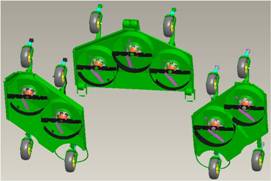

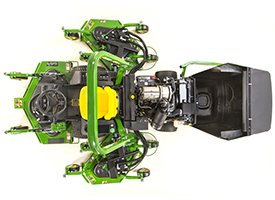

Mower decks have many performance and convenience features

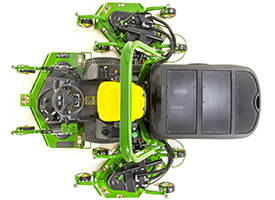

Wide-area mower (WAM) top view

Wide-area mower (WAM) top view  WAM front view with side mowers raised

WAM front view with side mowers raised  325.1 cm (128 in.) with both wings down

325.1 cm (128 in.) with both wings down  238.8 cm (94 in.) with center deck and either side deck down

238.8 cm (94 in.) with center deck and either side deck down  Front and side mowing

Front and side mowing  157.5 cm (62 in.) with center deck only

157.5 cm (62 in.) with center deck only The 1600 Turbo TerrainCut™ WAM is equipped with a 157.5 cm (62 in.) center deck and two 106.7 cm (42 in.) wings. Cutting widths are 325.1 cm (128 in.) using all three decks, 238.8 cm (94 in.) using the center deck and either wing deck, and 157.5 cm (62 in.) with the center deck only. All decks are rear discharge. Wings fold for transport and reduce the machine’s width to a narrow 213 cm (84 in.), so it can easily be driven along golf-cart-size paths or fit on a trailer. The wing decks will float 45 degrees above horizontal and 20 degrees below horizontal, following the ground contour.

Underside of 157.5 cm (62-in.) deck

Underside of 157.5 cm (62-in.) deck  Side view of 106.7 cm (42-in.) deck

Side view of 106.7 cm (42-in.) deck All decks have a unique baffling system that reduces clumping and provides even clipping dispersal for exceptional appearance.

Features common to these rear-discharge mower decks include:

- Mower decks are fabricated from 7-gauge, 4.6 mm (0.179-in.) steel, the thickest in the industry; strength has been designed into the 1600 Turbo TerrainCut™ WAM mower decks for increased reliability

- A 1.9 cm (3/4-in.) solid bar runs along the entire mower deck perimeter for added strength

- Dual-range height of cut spans 2.54 cm (1 in.) to 14 cm (5.5 in.) in 1.27 cm (0.5-in.) increment adjustments

- Wing deck float of 45 degrees upward and 20 degrees downward provides excellent cut quality when mowing undulating terrain

- Each wing deck has four caster wheels to follow ground contour and provide unmatched cut quality

- Unique baffling system produces even grass dispersal for superior appearance

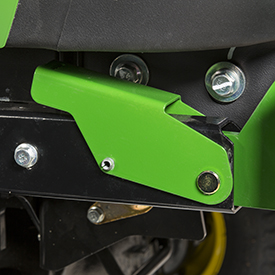

Patented impact-absorbing system

Patented impact-absorbing system

Patented impact-absorbing system

A patented impact-absorbing system is provided:

- This exclusive feature allows the wing decks to move rearward and inward when contacting obstructions such as trees, curbs, or other solid objects to prevent damage.

- Mowers are safety certified (meaning that mowers have been evaluated by the manufacturer [John Deere Turf Care] and conform to American National Standards Institute [ANSI] B71.4 Safety Certification Specifications for Commercial Turf Care Equipment).

Isolated deck motor design

Isolated deck motor design

Isolated deck motor design The isolated deck motor design consists of three cast-iron mounting structures for the deck motors. Rubber isolators that are similar to engine mount isolators are located between the castings and the deck shell brackets.

The rubber isolators allow the castings to flex relative to the deck shell. The addition of the isolators stops the vibration path between the hydraulic motor and the deck shell, thus preventing the amplification of sound by the deck shell.

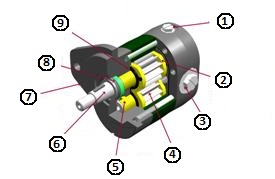

Deck motors

Deck motor

Deck motor  D Series deck motor

D Series deck motor - Radial case drain

- Pressure balanced bronze-on-steel thrust plates

- Flexible configuration of shaft, flange, and ports

- One-piece steel gears with 12-tooth profile

- Heavy-duty, low-friction sleeve bearings

- Integrated dust protector

- High-strength ductile iron body and covers

- High-temperature Viton® rubber shaft seals

- Figure 8 monolithic high-temp load seals

The deck motors are capable of withstanding high pressure requirements for all-day mowing. Motors have Viton seals, which can withstand higher hydraulic temperatures. The motor contains a dust seal to help eliminate debris from entering into the hydraulic connections.

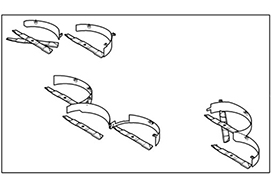

Mower mulch kit available

WAM mulch kit illustration

WAM mulch kit illustration  WAM mulch kit illustration

WAM mulch kit illustration A mulch kit is available as an attachment for field conversion. The mulch kit includes unique mulch blades, baffles, and a deflector shield to produce smaller clippings, which decompose faster than un-mulched clippings. Operators should follow the one-third rule when mulching grass.

This mulch kit also does an excellent job when mulching leaves.

BTC10335 TriCycler Mulching Kit

NOTE: Applicable for serial numbers starting with 1TC1600TPBT100007 and higher, model year 2012 and newer.

Viton is a trademark of The Chemours Company.

Lift valve

Lift valve

Lift valve The lift valve controls the cylinders that lift and lower the decks. It also controls the axial piston deck-motor pump (turns it on and off).

Mow valve

Mow valve

Mow valve The mow valve controls the hydraulic flow to the wing deck circuits.

Standard high-back, air-suspension seat provided for operator comfort

High-back, air-suspension seat

High-back, air-suspension seat An air-suspension seat is standard equipment and provides maximum operator comfort across a wide range of operator traits. Key adjustments include the following:

- Weight and height adjustment allow for proper ride and suspension height.

- Damper adjustment that allows the operator to adjust the seat’s ride to their preference:

- Softer settings increase seat travel to absorb large bumps.

- Stiffer settings reduce vertical seat travel, reducing movement of the operator’s arms and legs.

- Fore-aft seat slide adjustment helps account for a wide range of heights.

- Fore-aft suspension travel to improve directional changes during operation.

- Back angle tilt adjustment is included for the back portion of the seat.

- Lumbar adjustment provides proper back support.

- Standard, adjustable armrests are made of a durable material that provides adequate support and surface area for the operator's arms.

- High seat-back profile features body-contoured seat cushions.

- Cushions are ideal for those who seek proper back support. The highly-resilient contoured foam construction allows for all-day mowing comfort.

- A raised seat ensures a commanding view to the front and side mower decks.

- The retractable seat belt is convenient to use.

The comfortable seat, along with ample legroom in the operator's platform, convenient pedal locations, and adjustable steering column make operator comfort on the John Deere 1600 Turbo TerrainCut™ Wide-Area Mower among the best in the industry.

The standard air-suspension seat with adjustable armrests is designed with comfort, safety, and ergonomics in mind, ensuring relaxed, healthy sitting for hours on end.

Air-suspension seat adjustment

Air-suspension seat adjustment A-Armrest height

B-Lumbar

C-Fore-aft slide

D-Fore-aft suspension

E-Air-suspension weight and height

F-Damper

G-Back angle tilt

Controls and instrumentation are convenient and easy to find

Control console

Control console Low-effort controls are conveniently grouped on the right-hand side.

The finger-touch controls are:

- Left mower deck lift/lower switch

- Front mower deck lift/lower switch

- Right mower deck lift/lower switch

- Electronically-controlled throttle lever

- Electronically-activated power take-off (PTO) switch

- Speed-range lever for high, neutral, and low range

- Four-wheel drive (4WD) lever

Hydrostatic power steering

- Makes it easy to turn the machine, reducing operator fatigue

- Allows quick steering action, two and a half turns lock-to-lock, for excellent maneuverability

Two-pedal foot controls

Two-pedal foot controls

Two-pedal foot controls - Convenient two-pedal hydrostatic control system

- Allows the operator to select speed and direction with just a touch of the toe while resting heel on platform

- Twin Touch™ pedal design that allows the operator to change direction without having to lift his foot off the platform

- Large pedal surface, which provides increased operator comfort

- Keeps both hands free for steering and operating controls

Standard turning brakes

Standard turning brakes

Standard turning brakes The individual brakes can be applied by the operator as a traction aid or to reduce the turning radius.

Master stop brake

Master stop brake

Master stop brake - Brake is easy to use.

- Push-pull-type parking brake release allows the operator to simply pull out the knob and depress the foot brake to engage. To disengage, simply push the foot brake pedal and push the knob in to initiate release.

- Brake provides stopping power to both drive wheels.

- The stop brake is used for a parking brake.

Differential lock

Differential lock

Differential lock - Locks both front drive wheels together for added traction

- Increases traction and flotation in poor traction conditions

The differential lock is located on the left side of the platform; this allows for easy use of the Twin Touch foot pedals (on the right side) while engaging the differential lock at the same time.

High/low range lever

High-/low range lever

High-/low range lever - The high-/low range lever allows the operator to select the desired speed range.

- The machine must be stopped to shift between ranges.

- Shifting to the neutral position allows the operator to by-pass the hydraulic drive for towing.

4WD lever

4WD lever

4WD lever - The 4WD lever allows the operator to engage 4WD in reverse. 4WD is automatically engaged when wheel slip occurs in forward drive.

Electronic cruise control

Electronic cruise control

Electronic cruise control - Beneficial when mowing open areas or when transporting

- Located on the steering column

Cruise control operation

- To engage, simply push forward on the cruise control switch and hold until the foot is removed from the forward pedal.

- For an emergency stop, cruise can be released by pushing on the master brake pedal or turning the cruise control switch off.

Tilt steering

Tilt steering

Tilt steering  Headlights

Headlights - Allows the operator to adjust the steering column to the most comfortable position and provides additional clearance for entry to the operator station

- Two standard 20-W halogen headlights are located low in the column for the best illumination

Engine rpm screen

Engine rpm screen  System voltage screen

System voltage screen Optional light-emitting diode (LED) road light, beacon light, and work light attachments

LED road and work lights

LED road and work lights  LED road and breakaway beacon lights

LED road and breakaway beacon lights The road, beacon, and work light attachments are available in LED designs.

- BUC11407 breakaway LED beacon light kit is short to avoid damage.

- BUC11408 LED work light kit includes four front-mounted LED work lights.

- BUC11543 LED road light kit includes turn signals, warning flashers, taillights, mounting brackets, wiring harness, and turn signal switch. BUC11543 requires BUC11408 LED work light.

- BUC11407, BUC11408, and BUC11543 are compatible with model year 2018 and newer (serial number 500,001-) wide-area mowers.

Mower deck lift switches

Mower deck lift switches

Mower deck lift switches The mower deck switches allow the operator to vary mowing widths, engage and disengage the wing-deck blades, and service and transport the machine.

Easy-to-view operator instrumentation

Instrumentation from seat

Instrumentation from seat  Instrumentation panel

Instrumentation panel  Diesel particulate filter screen

Diesel particulate filter screen  Service menu screen

Service menu screen  Engine coolant temperature screen

Engine coolant temperature screen An instrument panel is located on the steering column for both operator convenience and safety.

Instrumentation includes:

Hour meter

Hour meter

Hour meter - Located on the steering column for easy viewing

- Records the number of hours the engine has run

- Used along with the periodic service chart (located in the engine compartment) to determine when service procedures need to be performed on the machine and mower deck

Engine glow plug light

The engine glow plug light indicates the intake manifold heater is energized. The operator should wait until the glow plug light goes off before starting the engine.

- The manifold heater is controlled by a temperature-sensitive timer and turns off sooner in warm weather.

- Starting the engine before the indicator turns off wastes fuel, creates smoke, and puts unnecessary wear on the starter.

- If the starter does not engage when the key switch is turned to the start position, one of the start conditions has not been met. Trouble codes are presented as a sequence of flashes and pauses that must be counted and converted to a two digit number:

- One flash, a short pause, and two flashes – operator attempted to start the machine without the park brake locked and the operator is off of the seat (one of these conditions must be met for the starter to engage).

- One flash, a short pause, and three flashes – operator attempted to start the machine with the power take-off (PTO) engaged.

- Two flashes, a short pause, and one flash – hydrostatic pedals are not centered in the neutral position.

Engine coolant temperature light

The engine coolant temperature light indicates the engine is overheating. A warning beeper also sounds when the light comes on.

Engine oil pressure light

The engine oil pressure light indicates the engine oil pressure is low. The indicator should be lit as a test to make sure it is working when the key switch is turned to the run position. A warning beeper sounds when the light comes on. The light (and beeper) should go off once the engine starts.

Battery discharge light

The battery discharge light indicates the battery is not getting enough charge from the alternator. The light should come on when the key switch is turned from off to run. The light should go off once the engine starts.

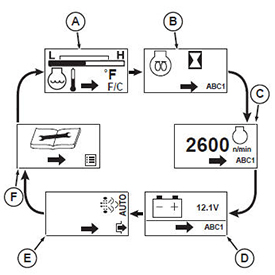

Primary display unit (PDU) navigation

Primary display unit

Primary display unit The PDU utilises three buttons for navigation.

The display’s top-level screens can be cycled through by pressing the center button.

Operator screens

Operator screens Top level screen functions are as follows:

A - Engine coolant temperature (ECT) screen

B - Pre-heat countdown (HPH) screen

C - Engine rpm (erpm) screen

D - System voltage (SV) screen

E - Diesel particulate filter (DPF) screen

F - Service menu (IServ) screen

The top-level screens are shown in order of display. To navigate to next top-level screen, press the center button on the PDU. For more information on the different functions, please refer to the machine’s operator’s manual.

Safety starting system

The 1600 Turbo TerrainCut™ Wide-Area Mower (WAM) has an operator-presence system.

In order to start the engine, the following must be met:

- The hydrostatic foot controls must be in neutral.

- The power take-off (PTO) must be disengaged.

- The operator must be in the seat or the parking brake must be set.

- The ignition key must be used.

In addition, once the engine is running, an interlock automatically shuts the engine and PTO off if the operator leaves the seat. To keep the engine running, the operator must disengage the PTO and set the parking brake before dismounting.

Tool tray and cup holder for operator convenience

Tool tray and cup holder

Tool tray and cup holder Tool tray and cup holder are convenient for the operator to get to:

- Quick access to a drink and tools on the machine decreases downtime.

Power take-off (PTO) drive provides control and power

Hydraulic PTO drive

Hydraulic PTO drive Mower decks are hydraulically driven using a separate closed-loop system with one gear-type motor for each deck:

- Mowers are designed to provide increased torque to the decks for additional power and productivity in tough mowing conditions.

- The operator can raise one or both of the wing decks and all hydraulic power will be directed to the center deck (exclusive John Deere feature) to provide maximum hydraulic pressure for extreme conditions.

- Blades are belt-driven from each deck motor.

Maximum productivity with hydrostatic transmission and transaxle

Hydrostatic transmission

Hydrostatic transmission A hydrostatic transmission is used for reliable operation.

Durability features include:

- Large, forged, one-piece trunnion shaft with large support bearings to reduce vibration and noise

- Charge pump used to efficiently deliver oil to the transmission

- Oil cooler to cool transmission oil for longer transmission life

- Pressure-side filtration to allow use of a finer mesh (10 micron filter) than suction filtration systems

High-range/low-range transaxle allows the following:

- High range has maximum speed of 24.1 km/h (15 mph) for faster transport. Power take-off (PTO) can be engaged for mowing in high range.

- Low range has a maximum speed of 14.5 km/h (9 mph). The wide-area mower (WAM) can mow in both low and high range.

Differential lock

Differential lock The differential lock is standard equipment:

- It locks both the front drive wheels together for extra traction, when needed.

- Conveniently located pedal allows the operator to engage the differential lock.

Planetary final drive and wet-disc brakes ensure durability and long life

Planetary final drive/wet-disc brakes

Planetary final drive/wet-disc brakes The planetary final drive (label 1 in the drawing) does the following:

- Evenly distributes stress load for long life

- Has heavy-duty drive axles for extra durability

Wet-disc brakes (label 2 in the drawing) do the following:

- Provide positive stopping power and long life

- Require minimal adjustment

- Include individual turn brakes as standard

Mechanical rear-wheel drive

1600 Turbo TerrainCut™ Wide-Area Mower (WAM) mechanical rear-wheel drive axle

1600 Turbo TerrainCut™ Wide-Area Mower (WAM) mechanical rear-wheel drive axle Two-function mechanical rear-wheel drive is standard equipment:

- On-demand four-wheel drive (4WD) automatically engages and disengages as needed. The machine operates in two-wheel drive (2WD) until front-wheel slip is detected. If front-wheel slip is detected, the machine then automatically engages 4WD in the forward direction.

- Constantly maximizes trimming ability

- Better fuel economy than full-time 4WD

- Less steering tyre wear than full-time 4WD

- Increases traction and trimming ability to allow a novice operator to mow like an expert

- Works in the forward direction only

-

- Full-time 4WD is on only when shifted into position by the operator.

- Can be engaged or disengaged on the go

- Provides maximum traction and flotation in difficult operating conditions

- Works in reverse as well as the forward direction

-

Features are provided for convenient transport

Wing decks raised

Wing decks raised The wing decks rise to a narrow 213.4 cm (84 in.) width and can be locked into transport position. A machine transport speed of 24.1 km/h (15 mph) means the operator can spend less time transporting and more time mowing.

NOTE: The power take-off (PTO) can be engaged while in the transport position.

Proper trailering strap areas

Fasten the machine to the trailer with heavy-duty straps, chains, or cables. Fasten the rear strap to the tow point bracket above the rear axle. Fasten the front strap to tie down holes on the operator's platform. Both the front and rear straps must be directed down and outward from the machine.

Bumper

Rear bumper

Rear bumper The rear, frame-mounted bumper provides for excellent rear protection and effective hood sealing for engine cooling.

To operate, pull out on the bottom of the engine cover latches on the left and right side of machine behind the operator’s seat. Unhook the tops of the engine cover latches from the hooks on the engine cover. Push down on the bumper lever and rotate the bumper to the right side of the machine.

Rear bumper latch in locked position

Rear bumper latch in locked position  Rear bumper latch in unlocked position

Rear bumper latch in unlocked position  Rear bumper in open position

Rear bumper in open position  Engine cover open

Engine cover open Manage your commercial mowing fleet using John Deere Operations Center™

TerrainCut™ Front and Wide-Area Mowers

TerrainCut™ Front and Wide-Area Mowers Overview

A JDLink™ M Modem - 4G connects a commercial mower to the John Deere Operations Center, which enables you to manage your fleet more efficiently, increase productivity, and reduce labor costs. With a modem and Operations Center, you are always connected to the work in progress and can make timely adjustments to keep your fleet mowing.

JDLink M Modem - 4G

JDLink M Modem - 4G

JDLink M Modem - 4G A JDLink M Modem - 4G is standard equipment on model year 2024 and newer TerrainCut Front and Wide-Area Mowers. A modem can be field installed on:

- Model year 2024 and newer Z700 ZTrak™ Mowers

- Most model year 2024 and newer Z900 ZTrak Mowers

- Model year 2024 and newer Q800 QuikTrak™ Mowers

- Model year 2022-2023 TerrainCut Front Mowers

- Model year 2023 TerrainCut Wide-Area Mowers

See compatibility section for serial number breaks and requirements.

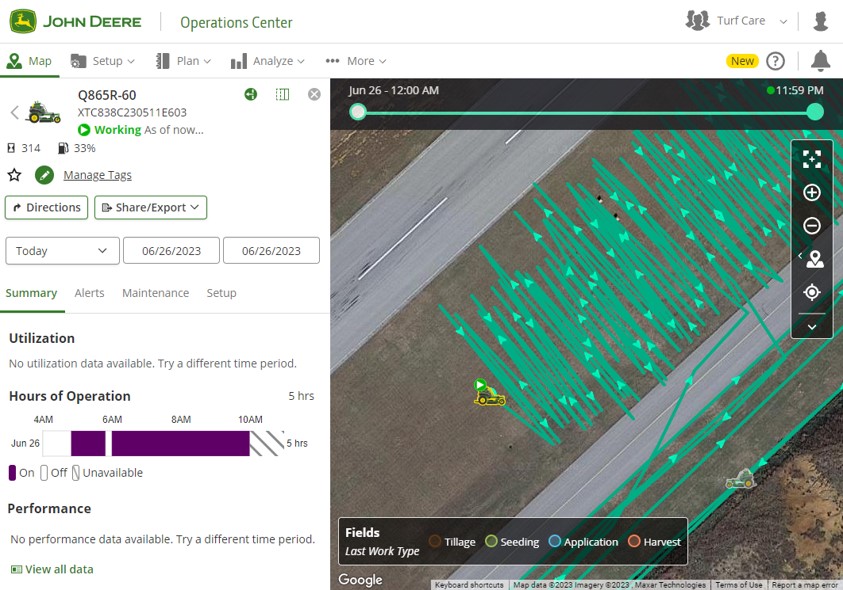

John Deere Operations Center

John Deere Operations Center is available on PC, Apple iOS, and Android mobile apps

John Deere Operations Center is available on PC, Apple iOS, and Android mobile apps The John Deere Operations Center tracks your fleet and provides tools to analyze mower data. The connected features vary by mower model.

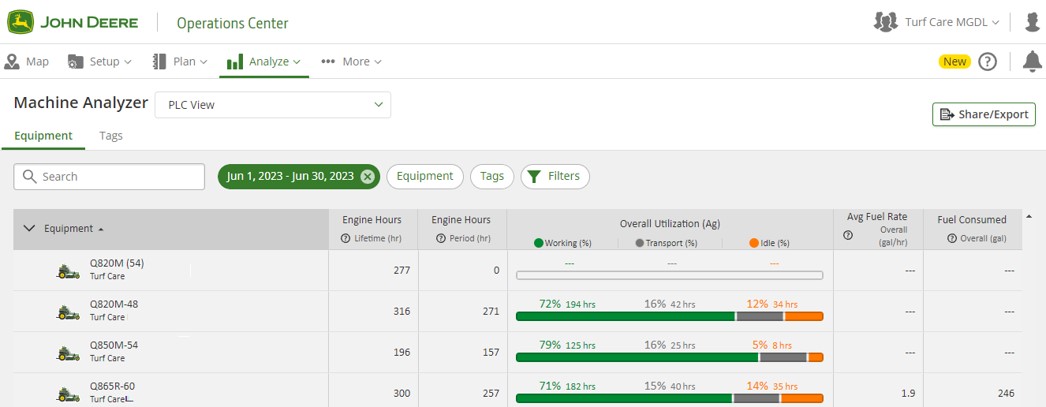

Models | Location and status | GPS speed | Geofencing and curfews | Engine hours | Maintenance planner | Machine Analyzer Tool | Fuel level | Fuel consumption | Diagnostic trouble codes | Service Advisor Remote |

Z700 ZTrak Mowers | X | X | X | Key | X | --- | --- | --- | --- | --- |

Gasoline-powered Z900 ZTrak Mowers | X | X | X | Key | X | --- | --- | --- | --- | --- |

Z994R ZTrak Mowers | X | X | X | Key | X | --- | --- | --- | --- | --- |

E Series QuikTrak Mowers | X | X | X | Key | X | --- | --- | --- | --- | --- |

Q820M, Q850M, and Q850R QuikTrak Mowers | X | X | X | Sync | X | X | X | --- | X | --- |

Q865R EFI QuikTrak Mowers | X | X | X | Sync | X | X | X | X | X | X |

1550 TerrainCut Front Mowers | X | X | X | Key | X | --- | --- | --- | --- | --- |

1570, 1575, 1580, and 1585 TerrainCut Front Mowers | X | X | X | Sync | X | X | --- | --- | X | X |

1600 TerrainCut Wide-Area Mowers | X | X | X | Sync | X | X | --- | --- | X | X |

Location and status

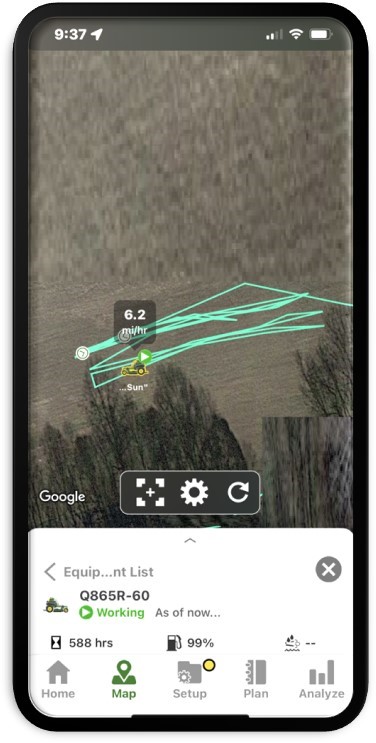

Operations Center map displaying past locations of a mower

Operations Center map displaying past locations of a mower  Mobile view of Operations Center map showing GPS speed

Mobile view of Operations Center map showing GPS speed The JDLink M Modem - 4G regularly transmits the location and operational status of each mower in the fleet so you can monitor mowing progress on the Operations Center.

- Location history-Display of map with current and past locations of each mower.

- GPS Speed-Maps each mower’s current and past speeds, based on GPS location data, so you can target operator training. GPS speed is only viewable on Apple iOS and Android mobile apps.

- Geofencing-Alerts when a mower enters or exits a prescribed area, for example if the mower has been stolen or an operator entered an area that should not be mowed.

- Curfews-Alerts if the mower is operating outside prescribed times, for example residential areas with early-morning noise restrictions.

Engine hours

The modem regularly transmits the mower’s engine hours to inform maintenance planning and balance use.

- Sync-The mower reports actual engine hours to the Operations Center.

- Key-Engine hours are estimated by monitoring the key switch. Engine hours can be corrected in Operations Center.

Maintenance planner

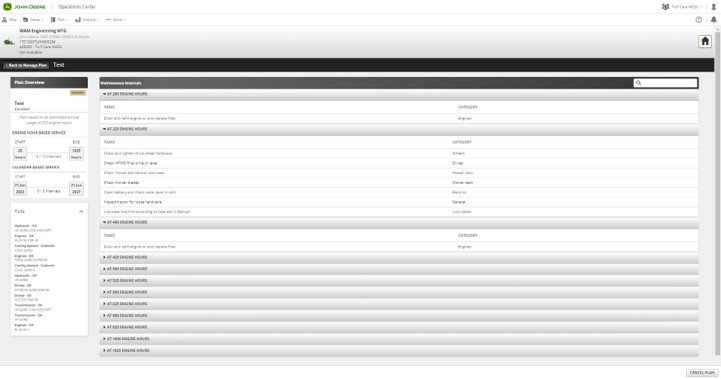

Operations Center Maintenance Planner

Operations Center Maintenance Planner Factory or custom maintenance plans can be established in Operations Center. Maintenance alerts are sent when engine hours reach maintenance intervals.

Machine Analyzer Tool

Operations Center Machine Analyzer Tool

Operations Center Machine Analyzer Tool On select products, the modem reports the time the mower spent transporting, idling, and working. The Operations Center’s Machine Analyzer tool reports usage data which allows you to analyze operator behavior, identify causes of low productivity, and initiate corrective actions.

Fuel level

On select products, the modem reports the fuel level. On these products, an analysis of fuel consumption is available in the Operations Center Machine Analyzer Tool. Measuring fuel consumption enables you to address causes of excessive fuel use.

Diagnostic trouble codes (DTCs)

On select products, the modem transmits the trouble codes generated by the mower’s control units to the Operations Center. Addressing DTCs can reduce downtime and repair costs. For example, a low-engine oil pressure DTC can indicate an engine is low on oil. Addressing the issue can prevent costly downtime and repairs.

Service Advisor Remote

On select products, John Deere dealers can perform remote diagnostics, software programming, and adjustments without the cost of a service call.

Compatibility

A JDLink M Modem - 4G is standard equipment on model year 2024 and newer (SN 110,001-) TerrainCut Front Mowers and model year 2024 and newer (SN 690,001-) TerrainCut Wide-Area Mowers.

A JDLink M Modem - 4G can be field installed on the commercial mowing products listed below. Field installation attachments simplify modem installation, and include brackets, mounting hardware, harness, and instructions. Field installation requires a JDLink M Modem - 4G to be ordered separately.

Model | Compatible model years | Installation attachment |

Z700 ZTrak Mowers | 2024 and newer (SN 080,001-) | BUC11759* |

Gasoline-powered Z900 ZTrak Mowers | 2024 and newer (SN 130,001-) | BUC11759* |

Z994R ZTrak Mowers | 2024 and newer (SN 070,001-) | BUC11759* |

Z997R ZTrak Mowers | 2021 and newer (SN 800,001-) | To be determined |

QuikTrak Mowers | 2024 and newer (SN 010,001-) | BUC11744* |

R Series commercial walk-behind mowers | To be determined | To be determined |

TerrainCut Front Mowers | 2022-2023 (SN 080,001-110,000) | BUC11797* |

1600 TerrainCut Wide-Area Mowers | 2023 (SN 680,001-690,000) | BUC11797* |

*Expected by early 2024

Serviceability is designed-in to reduce maintenance cost and increase uptime

Hood and seat platform open for excellent access

Hood and seat platform open for excellent access  Overhead view

Overhead view The hood and seat platform open for excellent access to the engine and drivetrain. All daily service points are located on the left side of the machine:

- Fuel fill

- Engine oil check

- Engine oil filter

- Hydraulic oil fill

- Hydraulic oil filter

- Air filter restriction indicator

- Engine coolant check

Front deck raised 70 degrees

Front deck raised 70 degrees  Wing deck raised 90 degrees

Wing deck raised 90 degrees The wing decks raise 90 degrees, and the front deck raises 70 degrees for excellent access.

No tools are required to access the mower deck belts.

Quick response (QR) codes link to owner information web pages

QR code label on seat base

QR code label on seat base To speed access to owner information web pages, a QR code is printed onto a product identification number (PIN) label located on the seat base near the control console. The owner information web pages that include links to:

- Safety and how-to videos

- Operator’s manuals

- Parts catalogues

- Maintenance reminder sheets

- Attachments

- Warranty statements

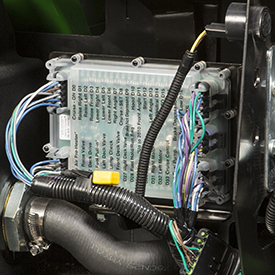

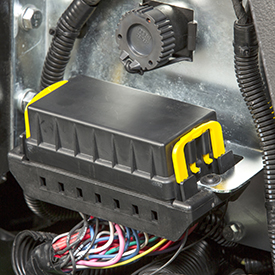

Diagnostic control module

Control module

Control module  Fuse box

Fuse box The diagnostic control module features light-emitting diode (LED) lights and a heartbeat to aid in diagnostics and lead the technician to the proper circuit. Each switch on the machine has its own LED light on the controller, so input and output functions can be diagnosed by observing the appropriate lights.

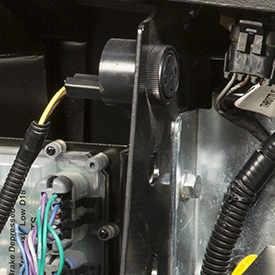

Service ADVISOR™ diagnostics system

Diagnostic port

Diagnostic port Service ADVISOR is a John Deere dealership tool capable of providing technical and machine support for technicians and service managers using a laptop computer. It provides symptom-based diagnostics information, machine information, electronic technical information, and connection to John Deere through an extranet at workshops and in the field.

A data port outlet socket is provided on the right-hand instrument panel next to the diagnostic control module console to access important service information with a laptop computer equipped with Service ADVISOR software. Service ADVISOR reduces downtime by allowing technicians to quickly identify the root cause of problems, aid them in identifying the component needing repair, and aid them in the repair procedures. It also significantly reduces the amount of printed materials the technician is required to have at their disposal to perform the repair or maintenance work.

Quick-access foot panel for easy access

Quick-access foot panel

Quick-access foot panel The foot panel is easily removed to allow quick and easy access to service points.

Excellent performance from high-traction tyres and low-maintenance caster tyres

Tyres

Tyres Large, 18x9.5-8 steering (rear) and 26x12-12 (front) drive tyres provide excellent traction and flotation. Both tyres have a six-ply rating.

Caster tyres

Caster tyre

Caster tyre Semi-pneumatic mower deck caster tyres are standard equipment. Benefits provided by semi-pneumatic tyres include:

- Looks and performs like a rubber air-filled tyre

- No flats means reduced downtime

- Reduces maintenance time and expense

- No need to worry about inflating caster tyres ever again

- Reduced incidents of caster tyres rolling off of the rim

- Semi-pneumatic tyres never need air maintenance, nor will they become flat when punctured, making them truly flat-free

Two-post folding Roll-Gard™ rollover protective structure (ROPS)

Two-post Roll-Gard ROPS

Two-post Roll-Gard ROPS  ROPS folded down for clearance

ROPS folded down for clearance The two-post folding Roll-Gard ROPS and seat belt are standard equipment:

- When used in combination with seat belts and safe operating practices, the ROPS is effective in reducing serious injuries and death from rollover accidents.

The standard-equipment Roll-Gard ROPS can be folded to allow for additional clearance when needed. With the ROPS in the folded-down position, the machine fits under a standard doorway.

The ROPS meets the International Organisation for Standardisation (ISO) 21299 ROPS standard – defined test procedures and acceptance criteria for the rollover protective structures of powered ride-on turf care machinery. Under the support of the Outdoor Power Equipment Institute (OPEI), a panel was formed that brought together an international group of ROPS experts that presented the best-learned practices regarding off-highway vehicle operator crush protection. The result of this undertaking is a standard dedicated to protecting operators of powered ride-on turf maintenance equipment.

The ROPS can be folded down without tools for operation under tree canopies or in other confined operating spaces. Operators should leave the ROPS in the upright position for all other mowing:

- The folding ROPS enhances operator safety and still provides clearance when loading on enclosed trailers.

Folding the ROPS is simple - remove two pins and rotate the top of the Roll-Gard ROPS down. Adjustments can be made from the operator's station.

The folding ROPS performance is certified at the date of manufacture, per the following standard:

- ISO 21299

Factory-installed, four-post rollover protective structure (ROPS) order option

Four-post ROPS

Four-post ROPS  Four-post ROPS side view

Four-post ROPS side view Due to the high percentage of operators who prefer the four-post ROPS canopy, a factory-installed option is available. The rear ROPS structure is a black fixed two-post ROPS.

The ROPS comes standard with a canopy and assembles to the 1600 Turbo TerrainCut™ Wide-Area Mower (WAM) along with a two-post

Roll-Gard™ ROPS.

The four-post ROPS structure includes the following:

- Two front posts

- Rear ROPS

- Welded top and bottom assemblies

- Molded canopy

The four-post ROPS provides the ability to meet bid requirements that call for a four-post ROPS and offers the ability to use a weather enclosure. It also meets the International Organization for Standardization (ISO) 21299 standard.