3038E

Compact Utility Tractor

- Standard four-wheel drive (4WD) for maximum traction

- Hydro transmission with Twin Touch™ pedals for ease of use

- On-board diagnostics including Service ADVISOR™

- Category 1 3-pt hitch compatible with dozens of implements

Features

Easy-to-use hydrostatic transmission (HST) increases tractor performance

The 3E Tractors are available with a two-range hydrostatic transmission (HST) incorporated in a die-cast aluminum transmission case. Fluid under pressure transmits engine power to the drive wheels via a closed-loop pump and motor arrangement. Infinite ground speeds allow the operator to match the speed of the tractor to the job.

- No clutching for fast and easy direction changes

- Twin Touch™ foot pedals for quick and easy forward/reverse operation

- Transmission oil cooler cools transmission oil for longer transmission life

Safety features of the HST include:

- The tractor will only start with the range lever in neutral

- The engine will shut off if the operator leaves the seat unless the range lever is in neutral

- The engine will shut off if the operator leaves the seat and the power take-off (PTO) is engaged

Twin Touch™ foot controls

Twin Touch foot controls

Twin Touch foot controls Key John Deere advantage - John Deere's Twin Touch foot controls offer several key advantages over competitive HST models tractors.

- Some competitive hydrostatic tractors use a treadle pedal (toe-heel) design foot control for operation of the HST

- Requires the operator to use both toe and heel to change direction, resulting in increased operator fatigue

- The Twin Touch configuration also makes it easier to "inch" the tractor forward or rearward (i.e. when attaching to implements)

-

Optional cruise control

Optional cruise control

Optional cruise control The 3E Series Tractors can be outfitted with an optional cruise control switch that is installed on the right-hand control console. This gives operators the ability to keep a constant speed when in transportation, field mowing, or other applications where extended use of the transmission is needed. This kit is very quick and easy to install for those who desire this feature.

Integrated hydrostatic pump and motor

- Sauer-Danfoss® company provides the integrated pump and motor; this assures that the components are matched to each other, providing maximum efficiency

- Reduces powertrain shock loads

- Provides strength and durability needed for operating such attachments as loaders

- One reservoir (with one check point and fill point) for the transmission, differential, and hydraulic system speeds up daily maintenance

- Mechanically actuated by Twin Touch foot pedals allow selecting both directions of travel and speed with the touch of a toe

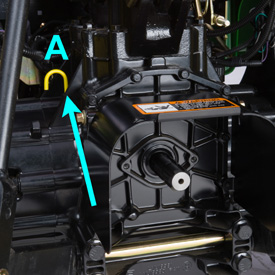

Transmission reservoir fluid checkpoint

Transmission reservoir fluid checkpoint (A)

Transmission reservoir fluid checkpoint (A) - Easy-to-reach transmission fluid dipstick allows for frequent checks of the transmission fluid level

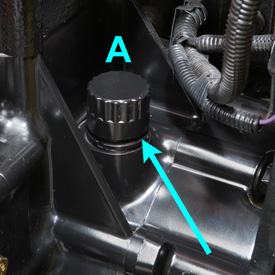

Transmission fill point

Transmission fill point

Transmission fill point - Easy-to-reach transmission fill point (A) located on top of rear axles on the right-hand side.

Integrated brake and differential lock pedal

Integrated brake and differential lock pedal

Integrated brake and differential lock pedal - Foot-actuated differential lock is integrated into the brake pedal to simplify operator controls; the differential lock is included as base equipment to assist traction in tough spots

- Press the brake pedal down half way to engage the differential lock that locks the rear axle for improved traction in tough spots

Sauer-Danfoss is a trademark of Sauer-Danfoss Incorporated.

Clean and simple operator station is comfortable and convenient

Clean and simple operator's station

Clean and simple operator's station An uncluttered design gives operators of all sizes plenty of room to be comfortable. Color-coded controls are located on either side of the operator.

- Hydrostatic transmission (HST) and brake pedals are designed and located for maximum comfort and ease of use.

- Contoured, comfortable seat enhances operator comfort.

- Seat position adjusts fore and aft

- Seat flips forward for protection from the elements.

-

- Flat operator platform provides for easy entry to/exit from the tractor.

- Folding Roll-Gard™ rollover protective structure (ROPS) and retractable seat belt increase operator safety.

Operator presence system:

- If the operator leaves the seat when the tractor is in gear, the engine shuts down

- If the operator leaves the seat when the power take-off (PTO) is engaged, the engine shuts down

Left-side step

Left-side step for easy entry/exit

Left-side step for easy entry/exit

- The left-side step allows for easy access on and off the tractor.

- Foot platform has a non-skid surface for sure footing.

Seat

The thick, soft padding on this seat provides a smooth and comfortable ride.

- Seat flips forward for protection from the elements.

- Adjustable using the fore and aft lever located under the seat, the seat slides on ramped rails to provide comfortable access to all controls.

Instrumentation

Instrument panel

Instrument panel Easy-to-read instrument panel includes the following:

- Tachometer

- Low oil pressure indicator light

- Battery discharge indicator light

- PTO engagement indicator light

- Signal/hazard lamp indicator lights

- Multi-function liquid crystal display (LCD) display (hours, filter cleaning information, etc.)

- Filter cleaning status indicator light

Fuel gauge

Fuel gauge

Fuel gauge All 3E Series Tractors come standard with a fuel gauge that is easy to read from the operator's station, to ensure operators do not run out of fuel.

Safety

Operator presence switch (OPS) in seat:

- OPS requires the operator to be in the seat to operate the transmission or PTO.

- ROPS is designed to meet or exceed American Society of Agricultural and Biological Engineers (ASABE) safety standards.

- Reflective ROPS strips for better tractor visibility.

- Seat belts are in base equipment on all John Deere compact utility tractors.

- Key switch interlock prevents bypass starting.

- Visual PTO warning light on the instrument panel alerts the operator when the PTO is running.

- Turn signal and flashing warning lights operate according to ASABE standards.

2-post Roll-Gard ROPS

Roll-Gard ROPS

Roll-Gard ROPS 3E Series Tractors are equipped with Roll-Gard ROPS. These folding ROPS meet the ASABE standards for compact utility tractors.

- Overall height is 244.3 cm (96.2 in.) with R3 tyres, 242.1 cm (95.3 in.) with R4 tyres, 244.6 cm (96.3 in.) with larger R4 tyres, and 244.9 cm (96.4 in.) with RI tyres. With the Roll-Gard ROPS folded down, producers can easily to get their tractor into a garage with a standard 2.1-m (7-ft) garage door.

NOTE: The use of seat belts is recommended at all times when operating the 3E Series Tractor with folding ROPS.

An optional canopy is available to help protect the operator from the elements.

Park brake

Park brake

Park brake

- Automotive hand-style park brake for easy on/off.

- Instrument panel has an indicator light for the park brake.

Optional two-spool rear selective control valve (SCV) for superior implement performance

Rear hydraulic remote kit

Rear hydraulic remote kit 3E Series Tractors can be equipped with a field-installed rear hydraulic remote kit, providing two additional hydraulic spools on the back of the tractor. This kit can be field installed on a tractor with a loader or without a loader.

NOTE: Not compatible with the power beyond kit.

The functions are completely separate from the loader. These rear remotes can be hooked up to a wide variety of implements and attachments such as follows:

- Hydraulically angled blade

- Hydraulically controlled chute/spout on a 3-point hitch-mounted snow blower

- Hydraulic scarifiers on a box blade

- Many other hydraulic rear attachments

This versatile kit gives 3E Series Tractor operators the options they desire for putting their tractors into a wide range of tasks.

NOTE: Neither of the spools in this kit are equipped with a detent position; therefore, they should not be hooked up to anything with a motor, as the valve was not designed to be run open. The kit is designed for momentary, on-demand hydraulic flow such as moving a cylinder.

Optional iMatch™ Quick-Hitch feature allows for easy implement hookup

iMatch Quick-Hitch (LVB25976)

iMatch Quick-Hitch (LVB25976) One of the greatest operator concerns involves difficulty in attaching tractor implements. John Deere has addressed this issue with the iMatch Quick-Hitch.

The iMatch Quick-Hitch provides easy hookup and a guaranteed fit for all Category 1 implements that are designed to meet the American Society of Agricultural and Biological Engineers (ASABE) Category 1 Standard S278.6 for quick-attach hitches.

- All implements require a set of bushings for the attachment to fit and work properly with the iMatch Quick-Hitch. One set of bushings comes with the iMatch Quick-Hitch.

NOTE: The bushing set can be seen in the picture above. These bushings allow the hooks on the iMatch and the pins on the implement to fit together properly. All other implements (box blades, tillers, rear blades, etc.) will require a set of bushings to enlarge the pin to fit with the iMatch hooks. Bushings of different lengths can be found in the parts system or through a bushing supplier (see dimensions below).

- Upper bushing

- Inside diameter: 1.93-1.95 cm (0.76-0.77 in.)

- Outside diameter: 3.15-3.18 cm (1.24-1.25 in.)

- Lower bushings

- Inside diameter: 2.24-2.26 cm (0.88 to 0.89 in.)

- Outside diameter: 3.63-3.66 cm (1.43 to 1.44 in.)

Excellent serviceability reduces operational costs and improves productivity

Regular service and maintenance are essential to the performance, productivity, and longevity of the tractor.

- Easy access to most regular service points minimises service time.

- Four quarter-turn fasteners allow operators to easily remove the engine side panels without tools to access the engine compartment.

- Quarter-turn fasteners allow tool-less access to engine

- Hydraulic oil service interval is increased to 1200 hours when using Hy-Gard™ products. Hydraulic oil filter will need to be changed every 400 hours.

- Tractors are equipped with extensive onboard self-diagnostic capabilities and are fully compatible with the John Deere-exclusive Service ADVISOR™ system.

- Daily service requirements are minimal and simple to accomplish. Most service interval requirements can be performed with a basic understanding of procedures and common tools

Fuel tank is located on the rear of the tractor to allow for easy access when fueling

Fuel tank is located on the rear of the tractor to allow for easy access when fueling

Fuel tank is on rear of tractor

All items in the daily service schedule can be performed without the use of tools:

- Engine oil, hydraulic oil, coolant level, and the water separator can be conveniently accessed.

- The engine can be easily accessed by simply raising the hood for more periodic maintenance checks.

- A single-point latch mechanism and self-contained leash ensure easy hood opening and closure.

NOTE: Always refer to the operator’s manual for complete maintenance and service recommendations.