6155M

Utility Tractor

- PowerTech™ E (Tier 2) / PowerTech PVS 6.8 L (FT4)

- Category 3N/3, 3-point hitch

- MFWD with optional TLS™ Plus

- OOS (FT4 only)/CommandView™ Cab

Features

Improved operator experience inside updated cab

Updated cab

Your 6M workspace is all about intuitive and straightforward tractor operation. Guided by best-practice ergonomic principles, the design of the 6M Tractor's right-hand console and the compact CommandARM™ console is perfectly aligned with the updated cornerpost display in the A-post. It’s a smoothly productive operator experience that is enclosed by more glass all around for a wide-open, unencumbered view.

6M Tractor cab

6M Tractor cab  Compact CommandARM console

Compact CommandARM console  Cornerpost display in A-post

Cornerpost display in A-post Bright and long-lasting illumination with lighting packages

Illumination

Factory-installed lighting packages deliver a wide, bright, and concentrated field of light all around your 6M Tractor. For even more demanding lighting requirements, you’ll want to opt for the light-emitting diode (LED) lighting packages which consume less power, provide an even brighter daylight-quality light, and last longer.

360-degree visibility from lighting packages with up to 12 cab lights

360-degree visibility from lighting packages with up to 12 cab lights Performance boost from high-powered engines

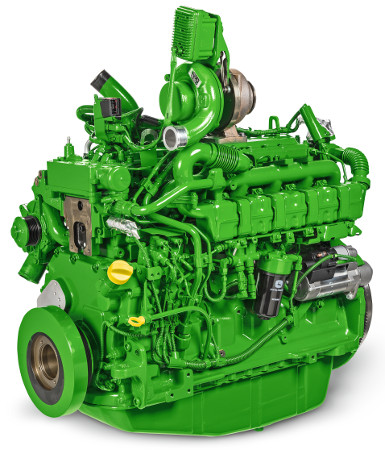

Engine

Get all the power you need with less fuel and lower emissions from the 4.5L (274.6-cu in.), 4-cylinder engine or 6.8L (415-cu in.), 6-cylinder engine. Both are ready for Final Tier 4 (FT4)/Stage V emission standards. The 6-cylinder engine features extended drain intervals of up to 750 hours with John Deere Plus-50™ II oil.

4.5L (274.6-cu in.) EWL engine

4.5L (274.6-cu in.) EWL engine The higher power output of the 6-cylinder engine comes from refined high-pressure common rail (HPCR) technology with injection pressure of up to 2,500 bar (36,259.4 psi). The PVS engine in the 6155M, 6175M, and 6195M Tractors has a variable geometry turbocharger (VGT) that boosts performance and efficiency across the torque curve.

6.8L (415-cu in.) PVS engine

6.8L (415-cu in.) PVS engine Outstanding efficiency and power with transmission portfolio

Our proven transmission portfolio combines superior ease of operation and convenience with outstanding efficiency to complement the power and torque of your 6M Tractor. For the 6090M through 6155M models, a creeper option with speeds as low as 0.072 km/h (0.05 mph) at 1,000 rpm is available.

PowrQuad™ Plus transmission

Three versions are available: 16F/16R, 20F/20R, and 24F/24R. All provide rapid shifting including speed matching for smooth shifting between ranges. They are operated by a single range lever with declutch function and push-button gear selection. SoftShift technology keeps the changes smooth, even under load.

PowrQuad Plus

PowrQuad Plus AutoQuad™ Plus transmission

The AutoQuad Plus transmisison provides all the benefits of PowrQuad Plus with the added convenience of automatic gear shifting. 20F/20R and 24F/24R versions are available. The EcoShift option combines high transport speed (40 km/h [24.9 mph]) and low engine rpm between 1,580 and 1,680 to reduce fuel consumption and emissions by up to 23 percent.

AutoQuad Plus

AutoQuad Plus CommandQuad™ Plus transmission

Looking for that extra level of operational ease? Say hello to a lot less clutching and experience less tiresome, more productive days in the cab. You’ll love the enhanced automatic capabilities of CommandQuad Plus.

CommandQuad Plus

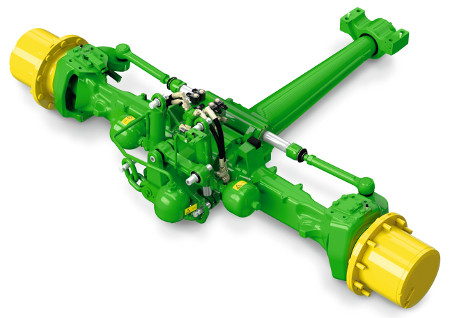

CommandQuad Plus Comfort and stability from the frame and optional suspension systems

Comfort and stability

The John Deere full-frame design is a solid platform that absorbs and resists loads and shocks from the wheels, heavy implements, and front loaders. To further minimize the fatigue and stress caused by unpleasant vibrations, 6M Tractors can be specified with optional mechanical cab suspension. The standard front axle delivers superior on-road handling, and Triple Link Suspension (TLS™) is optionally available.

TLS

TLS  Mechanical cab suspension

Mechanical cab suspension Fuel efficiency and machine performance with hydraulic system

Hydraulics

Easily controlled via the cornerpost display, the pressure-and-flow compensated system (PFC) of the 6M Tractors will produce a powerful flow of up 114 L/min (30.1-gpm). The system automatically enters a no-flow standby mode that improves fuel efficiency, implement performance, and steering response. For operations with less demanding tasks, a cost effective and more basic pressure compensated system (PC) with 80-L/min (21.1-gpm) flow is also available.

The selective control valve (SCV) stack groups together up to four SCVs, power beyond couplers, and the pressure-free return circuit valve, with hydraulic flow easily adjusted from the cornerpost display.

SCV stack

SCV stack Match the tractor axle to the operation

Axles

Depending on the tread adjustment requirements of the jobs you mostly work on with your tractor, you can choose between flange axles or rack-and-pinion axles on your 6M Tractor.