XUV865E

Crossover Utility Vehicle

- Three person cockpit

- Adjustable driver’s seat with tilt steering

- Over 57 L (16 gal.) of enclosed storage

- Powerful diesel engine system

Features

Superior terrain capability

The Gator™ XUV Crossover Series Utility Vehicle has a precision-engineered drivetrain system that fully utilizes engine power, optimizing acceleration, hauling, towing, and hill-climbing capabilities. Power is transmitted from the engine through a continuously variable clutch system to the transaxle.

Key elements of the drive system include:

Variable-speed drive

Variable-speed drive

Variable-speed drive The variable-speed drive consists of two clutches and a drive belt:

- Drive clutch is attached to the engine.

- Driven clutch is attached to the transaxle.

Features include:

- The engine braking system utilizes a tight belt for operation, requiring an idler sleeve on the primary clutch for neutral. The secondary clutch is a build- on-shaft design that utilizes a cam to tune the acceleration and deceleration of the vehicle. The clutch stays engaged, providing deceleration until approximately 5 km/h (3 mph).

- The continuously variable transmission (CVT) air intake draws in cool air to reduce heat and the amount of water ingestion into the CVT system. The system reduces belt slippage and improve durability.

- A two-range transmission provides:

- Ability to maneuver in tight spaces and increased pulling torque in low range

- Faster speeds and reduced transport time in high range

- Standard full-clutch enclosure with high-speed fan provides longer belt and clutch life

- High-ratio clutches with three cam weights for maximum belt-clamp load in high torque conditions

How the variable-speed drive works:

- As engine speed increases, the spring-loaded drive clutch is closed by weights being forced out by centrifugal force.

- As the drive clutch closes, the belt rides up to the largest diameter of the drive clutch and forces open the driven clutch.

- With the belt running in the smallest diameter of the driven clutch, the speed being transferred to the transaxle is increased.

- The driven clutch is designed to sense varying loads (inclines, mud, etc.) and constantly adjusts drive speed upward or downward so that engine rpm remains optimal.

Transaxle, four-wheel drive (4WD), and constant velocity (CV) shafts

Side view of CVT intake and clutch enclosure (XUV835M shown)

Side view of CVT intake and clutch enclosure (XUV835M shown)  Differential lock and 4WD switches

Differential lock and 4WD switches  Rear view of transaxle, suspension components, and CV shafts (XUV865M shown)

Rear view of transaxle, suspension components, and CV shafts (XUV865M shown)  CV boot protection

CV boot protection Operator interface features:

- Selectable 4WD system with a limited slip front differential and dash-mounted electronic rocker switch

- Provides exceptional traction in challenging conditions

- Near instantaneous torque to the front wheels once rocker switch is engaged

- Maintains turf-friendly operation in two-wheel drive (2WD) mode

- Combined with rear traction assist (differential lock), provides excellent traction in challenging conditions

- More control descending hills with 4WD engaged as all four wheels help slow the vehicle down

- Clutch engagement still necessary to prevent free coasting

Transaxle features:

- Low, high, neutral, reverse, and park transaxle

- Automotive-style, integrated park position in transmission

- Low range for maximum torque delivered to the wheels for hauling, pushing, and pulling

- High range for maximum vehicle speed

- To shift out of park, service brake must be pressed to release the parking solenoid. An audible click will be heard and allows the vehicle to shift out of park into the desired gear.

NOTE: Differential design reduces scuffing of the turf during turns because it allows the inside wheels to turn slower than the outside wheels.

- Start in gear, neutral, or park position for quick starting. The service brake must be engaged to start when in gear or neutral.

- For operators living in regions with homologation requirements or certain bid language stating the need for a secondary park brake, such as governmental or municipalities, a secondary park brake is available as a factory-installed option. A secondary brake attachment is not available for field installation.

- Large, sealed bearings are located inside the housing for better protection and durability

- Contains gear case for transferring power to the 4WD

- Splined shaft interfaces for maximum torque transfer and durability

- All drive gears machined from highest grade gear steel

- Protected by a skid plate

4WD features:

- Electronically selectable by the operator

- Offers limited slip functionality for precision steering and great traction while pointing and shooting out of a corner.

- Vertically oriented oil drain for easy maintenance

- Protected by a steel skid plate and frame

Drive shaft features:

- Rear CV shaft diameter measures 27 mm (1.1 in.) and is designed for peak engine and braking torque

- Front CV shaft diameter measures 23 mm (0.91 in.) and is designed for peak engine torque

- Propshaft is designed for peak engine torque

- All CV shaft and propshaft joints are maintenance free and protected by exclusive thermoplastic elastomer (TPE) boots for durability

Roomy and quiet operator station

Whether it is a completely open operator station or a factory-installed cab, the interior has been redesigned with comfort and ergonomics in mind.

- Gear shift control, four-wheel drive (4WD), and differential lock switches on the dash

- Tilt steering

- Available 40/60 split three-passenger bench seat with driver adjustment

Gear shift control with differential lock and 4WD switches (R Trim)

Gear shift control with differential lock and 4WD switches (R Trim)  Tilt steering

Tilt steering  Tilt steering (up position)

Tilt steering (up position)  Tilt steering (down position)

Tilt steering (down position)  Driver adjustment shown on 40/60 split three-passenger bench

Driver adjustment shown on 40/60 split three-passenger bench  Three-wide seating

Three-wide seating Powerful diesel engine delivers superb starting, idling, and throttle response

854-cc (52.1-cu in.) diesel engine

854-cc (52.1-cu in.) diesel engine The machine is powered by an 854-cc (52.1-cu in.), 3-cylinder, liquid-cooled, four-cycle diesel engine. It produces 48 Nm (35.5-lb-ft) of torque at 2600 rpm.

The advanced engine delivers superb starting, idling, and throttle response during operation.

The engine offers the following performance and reliability features:

- Indirect-injection diesel with glow plugs ensures fast starts in cold temperatures

- 17 kW (22.8 hp*) at 3600 rpm

- Overhead valve design for greater efficiency and fuel economy

- Spin-on oil filter for easy servicing

- Quiet operation through the entire rpm range

- Molybdenum-coated pistons

- High-stiffness cylinder block and gearcase

- High-flow water pump and optimized water jackets maintain a steady operating temperature and eliminate hot spots

- Full-pressure lubrication system

- In-line mechanical fuel pump

- Five-point, rubber isolated for quiet operation and minimal vibration

- Dry replaceable dual-element air cleaner with a restriction indicator

- See-through coolant recovery tank permits the operator to check the coolant level without removing the radiator cap

- Open front grille allows proper air flow and ventilation to the radiator.

*The engine horsepower information is provided by the engine manufacturer to be used for comparison purposes only. The actual operating horsepower will be less.

Dual A-arm front and rear suspension provides a smooth ride over challenging terrain and excellent hauling characteristics

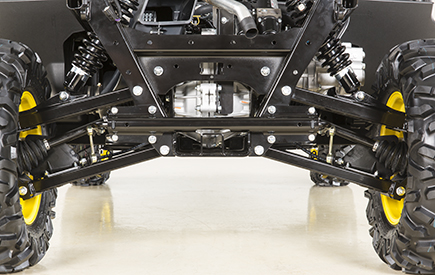

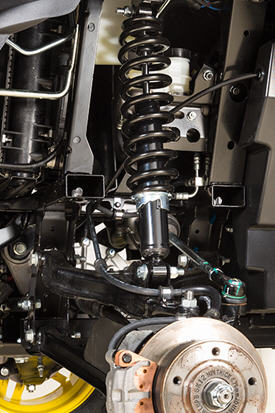

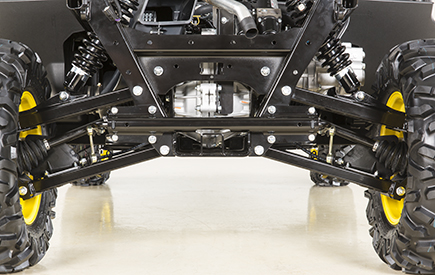

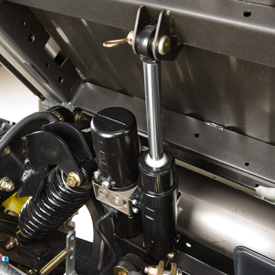

XUV front suspension detail

XUV front suspension detail To complement the robust frame, the XUV is equipped with four-wheel independent suspension.

A dual A-arm front and rear suspension provides a smooth ride over challenging terrain and excellent hauling characteristics.

The entire suspension system has been optimized to handle no cargo to maximum cargo without compromising ride quality or vehicle stability.

M-trim vehicles with factory-installed cabs and R-trim vehicles have heavy-duty front and rear shocks installed from the factory.

- A higher spring rate and higher preload force versus standard springs prevent the vehicle from sagging with a heavy payload.

- These heavy-duty shocks help with the heavier weight of the cab and when attachments are installed, like blades.

Dual A-arm independent front suspension features include:

- 203 mm (8 in.) of travel provides ample wheel travel to keep all four wheels on the ground for superior traction, excellent ride quality, and vehicle control

- Heavy-duty nodular cast-iron knuckles support the constant-velocity (CV) shaft and wheel

- Maintenance-free rubber torsional A-arm pivots for long life and quiet operation

- CV shaft protection from sticks that may puncture the rubber boot

- Coil-over shocks absorb the most demanding terrain

XUV rear suspension detail

XUV rear suspension detail  XUV rear suspension detail (shown on XUV865M)

XUV rear suspension detail (shown on XUV865M) Dual A-arm independent rear suspension features include:

- Unequal length and dual A-arm construction for superior wheel control and travel

- 229 mm (9 in.) of total travel provides ample wheel travel to keep all four wheels on the ground for superior traction, excellent ride quality, and vehicle control

- Coil-over shocks absorb the most demanding terrain

- A-arms made from square/rectangular tubing reduce weight while remaining rigid

- Heavy-duty nodular cast-iron uprights support wheel loads with a double row of ball bearings

- CV driveshaft protection from sticks that may puncture the rubber boot

- Rear sway bar for lateral stability

Extra-durable deluxe cargo box ensures hard-working performance and longevity

Deluxe cargo box with optional brake lights, taillights, and light protectors

Deluxe cargo box with optional brake lights, taillights, and light protectors  Top view of deluxe cargo box with optional spray-in liner

Top view of deluxe cargo box with optional spray-in liner The deluxe cargo box consists of a 15 percent glass-filled polypropylene composite material that eliminates rust and dents and reduces noise.

Deluxe cargo box tailgate

Tailgate handle

Tailgate handle  Tailgate open

Tailgate open  Tailgate lowered to 150 degrees

Tailgate lowered to 150 degrees The tailgate can be opened or removed for easier cleanout and to carry longer items. The tailgate features truck-like performance and can be operated with one hand.

The standard-installed lanyards can also be removed to lower the tailgate to 150 degrees for convenient loading and unloading tasks.

Deluxe cargo box tilt

Integrated handle for manual cargo box tilt

Integrated handle for manual cargo box tilt The deluxe cargo box is easier to latch, unlatch, raise, and lower with the integrated handle design and gas assist.

A prop rod is provided to hold the box in the upright position for operator convenience, as well as limit box pivot travel.

Integrated tie-down points

Integrated tie-down point in cargo-box bed

Integrated tie-down point in cargo-box bed  Additional tie-down points (TH 6X4 shown)

Additional tie-down points (TH 6X4 shown) The deluxe cargo box offers integrated tie-down points for increased versatility. Tie-down points are located in the following areas:

- Four corners inside the cargo box bed

- Four points on the load guard directly behind the operator station (A)

- Tie-down bars on either side of the cargo box (B)

- Six points on the underside of the cargo box frame (circled)

Converting deluxe cargo box to a flatbed

XUV835M Cab shown

XUV835M Cab shown  XUV835M Cab shown

XUV835M Cab shown The deluxe cargo box easily converts to a flat bed. The flatbed configuration allows loading larger cargo.

Optional accessories

Brake and taillight with optional protector

Brake and taillight with optional protector  Cargo bed mat

Cargo bed mat  Cargo box power lift

Cargo box power lift Optional accessories for the deluxe cargo box include:

- Factory-installed brake lights and taillights

- Taillight protectors

- Factory-installed spray-in liner that improves skid resistance and surface abrasion protection

- Cargo box bed mat to protect the steel floor from dents

- Factory-installed cargo box power lift

Specifications

| Length | 1143 mm (45 in.) |

| Width | 1320 mm (52 in.) |

| Depth | 305 mm (12 in.) |

| Volume | 0.46 m3 (16.4 cu ft) |

| Weight capacity | 454 kg (1000 lb) |

| Dump angle | 47 degrees |

CAUTION: Carrying extra-long cargo that extends beyond the box can adversely affect stability.

Customize with factory installed options and attachment-ready electrical system

Factory-installed options

Several popular attachments can be ordered with the vehicle:

- Roof on E- and M-trim open station vehicles (included with cab)

- Front glass windshield on M-trim open station vehicles (included with cab)

- Rear glass panel on M-trim open station vehicles (included with cab)

- Brush guard (standard on Honor and Signature Edition)

- Brush guard extensions

- Rear bumper (standard on Signature Edition)

- Front fender guards

- Rear fender guards and rear fender flares (standard on Signature Edition)

- Cargo box power lift (standard on Honor and Signature Edition)

- Deluxe cargo box with spray-in liner, brake lights, and taillights (standard on Honor and Signature Edition)

- Winch on M- and R-trim vehicles (except Honor and Signature Editions)

Electric power-assist steering (EPAS)

E-trim vehicles have manual steering; an M-trim or R-trim vehicle is needed for power steering.

Factory cabs

E-trim vehicles are only built in an open-station configuration. M-trim vehicles are built in both open-station and cab configurations. Cab components can be purchased as attachments for field conversion, however an M-trim vehicle with a factory-installed cab is recommended. All R-Trim vehicles are built with a factory cab.

Attachment-ready electrical system

All vehicles include wires and connectors for attachments like cargo box lift, brake lights, and taillights. Adding attachments to M- and R-trim vehicles is simplified because the base vehicle’s wiring harness includes connectors for additional attachments. See the following chart for details.

| Cargo box lift | Backup alarm | Brake / tail / reverse lights | Base radio speaker kit | Heater | 2041-kg (4500-lb) winch | Premium radio speaker kit | LED lights-front OPS | Windshield wiper | Windshield washer | LED lights-brush guard | LED headlights | Turn signals | Horn | Beacon light | LED lights - rear OPS | Sprayers and spreaders | Hydraulic blade | AMS integration kit | |

| E | a | a | a,c | a,c,d | a,c,d | a,c,d | a,b | a,b | a,b | a,b | a,c,e | a,c,e | a,f | a,f,g | a,c,e,f | ||||

| M open | c | c,d | c,d | c,d | b | b | b | b | c,e | c,e | f | f,g | c,e,f | ||||||

| M cab | b | b | b | b | e | e | f | f,g | e,f | ||||||||||

| R | f | f,g | f |

| = connections in base harness | |

| a | E-spec attachment harness |

| b | Front attachment harness |

| c | Roof attachment harness |

| d | Front cab attachment harness |

| e | Rear cab attachment harness |

| f | Front attachment (dash port) harness |

| g | Hydraulic blade and winch harness (only needed if hydraulic blade and winch are installed on same vehicle) |

| * | If blank, the base chassis harness has the connector for the attachment |

Headlights

E- and M-trim vehicles have single beam halogen headlights. R-trim vehicles have single beam light-emitting diode (LED) headlights. The following attachments can be used to upgrade vehicles to dual beam LED headlights.

XUV835E and XUV865E

- BM26589 dual beam LED headlights, including three-position rocker switch

- BUC10809 front light harness kit

- BUC10810 E-spec attachment harness

XUV835M and XUV865M:

- BM26589 dual beam LED headlights, including three-position rocker switch

- BUC10809 front light harness kit

XUV835R and XUV865R:

- BM26589 dual beam LED headlights, including three-position rocker switch