V451G

Variable Chamber Baler

- High capacity, high performance 2.2 m wide feeding system

- High Capacity Rotor: 480 mm diameter converging auger

- 1.65 m maximum bale diameter in a 1.21 m wide chamber allows you to maximise bale weight for straw or hay

Features

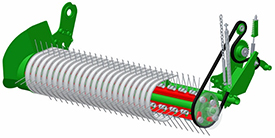

2.2-m (7.2-ft) cam-track pickup harvests large swaths

2.2-m (7.2-ft) width facilitates swath feeding

Four tine bars ensure optimal pickup capacity

Four tine bars ensure optimal pickup capacity Directly derived from well-known 900 Series components, the V451G Baler features a 2.2-m (7.2-ft) width pickup (1.92-m [6.3-ft] tine-to-tine width) that easily grabs large straw or hay swaths. The 5-mm (0.2-in.) tine diameter, teamed with a four-tine bar pickup match-picking capacity, is traditionally expected by small and mid-size farms.

The V451G Baler pickup does not need any shear bolt or cam-clutch protection — tines are designed to fold in case of foreign objects or potential overload. The overall system is protected by the bending capacity of the tines. Tines have been tested for hours and feature an extended lifespan. The sealed ball bearings on each side offer a quiet ride.

To give good gliding capacity and maintain performance levels, pickup strippers are made from high-quality galvanized steel that prevents the material from rusting.

Cam-track design offers the best versatility

Left, pickup with cam track; right, cam-less pickup

Left, pickup with cam track; right, cam-less pickup Even though the best results may come from baling in dry crops, the V451G Baler is fully able to harvest haylage or regular silage. The V451G Baler pickup features a versatile cam-track technology.

Cam-track technology provides an efficient solution for such needs. The traditional stripper design provides reduced space between the pickup tines and rotor feeder, while the tine motion helps to avoid pinching. The cam-less technology requires long strippers, creating a dead zone between the tines and rotor. Additionally, fixed tines can easily pinch crops in sticky conditions, causing plugs that need to be manually removed.

The cam-track pickup features an 18 percent lower turning speed than on the previous generation of balers, while bearings have been implemented on both sides of the tine bars. The cam levers have switched to forged steel and the cam bearings size has increased by 36 percent. All these features lend themselves to a long component life that cannot be compared to the old pickup design.

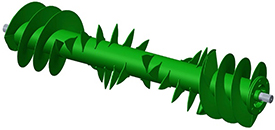

RotoFlow High Capacity (HC) rotor grabs the toughest swaths

The V451G benefits from the proven HC rotor concept featuring an in-line design

Rotor and converging augers are aligned on a single axle

Rotor and converging augers are aligned on a single axle  Left, HC rotor; right, classic rotor design

Left, HC rotor; right, classic rotor design By using the HC rotor – a concept implemented on John Deere round balers since 2012 – the V451G feeding system offers:

- Limited distance from the pickup to the rotor tines to reduce plugging, especially in brittle straw or short silage

- Reduced number of bearings and distributed loads along the rotor to increase reliability

- Large 48-cm (18.9-in.) diameter converging augers to facilitate crop transfer

The overall result is an optimized crop flow that avoids all dead area where crops stay for a long time. This smooth and regular crop flow guarantees high feeding capacity, especially in short or sticky crops.

RotoFlow HC is the perfect solution for straw and hay

Simple rotor design

Simple rotor design The V451G Round Baler is equipped with the RotoFlow HC non-cutting rotary feeder. As with the RotoFlow HC Premium, available on M- and R-Series Variable Chamber Balers, the V451G RotoFlow features:

- Close to 50-cm (19.7-in.) diameter rotor for high inertia and feeding capacity

- Hardox® wear plate material that provides long lifespan and high resistance to foreign objects (Hardox wear plate tines provide 80 percent or more resistance versus traditional S700 grade steel)

- Similar rotor and converging auger diameter

Compared to the RotoFlow HC Premium, the RotoFlow HC equipped on the V451G only features two tines per turn (instead of three tines on the M-/R-Series) and spikes (instead of tines fully enclosing the tube on the M-/R-Series).

Simple but efficient unplugging system gives producers peace of mind

Rotor rotation can be easily unclutched from rest of the baler

Rotor rotation can be easily unclutched from rest of the baler In case of a plug, crops can be easily removed from the feeding system. The V451G can be unplugged without the operator reaching their hands into the pickup. The operator needs to leave the cab to declutch the rotor, put the wrench on the rotor, and reverse to remove the compressed crops. This is a simple but cost-efficient solution.

Hardox is a trademark of SSAB Technology AB.

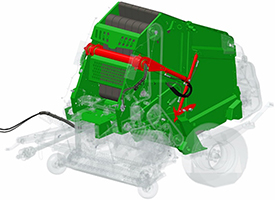

Bale chamber delivers heavy, dense, and perfectly shaped bales

Bales up to 1.65-m (5.4-ft) in diameter maximize weight for optimal density

1.65-m (5.4-ft) x 1.21-m (3.97-ft) bales

1.65-m (5.4-ft) x 1.21-m (3.97-ft) bales As for fixed chambers or M-/R-Series Variable Chamber Balers, the V451G Baler features a 1.21-m (3.97-ft) bale chamber width. Compared to previous generation balers with similar bale diameters, bales are up to 3.6 percent bigger than before. Considering a similar density, that is a huge advantage.

The bale diameter on the V451G Baler can be adjusted from 1 m (3.3 ft) to 1.65 m (5.4 ft) from the monitor. The maximum diameter of 1.65 m (5.4 ft) is an added 10 cm (3.9 in.) compared to the previous generation. This allows the grower to produce bales up to 17 percent larger than previous 852/854 Balers and facilitates production of similar 1.6-m (5.25-ft) hay and straw bales.

Bale diameter progress can be followed from the cab with BaleTrak™ monitor as soon as the bale is larger than 1 m (3.3 ft).

High density provided regardless of bale diameter

Dedicated cylinders for tailgate and density system plus mechanical tailgate lock

Dedicated cylinders for tailgate and density system plus mechanical tailgate lock  Simple density settings from the baler side

Simple density settings from the baler side The bale chamber on the V451G Baler provides high-density bales regardless of the bale diameter or crop type. A dedicated pair of cylinders applies strength to the density arm while mechanical hooks firmly lock the tailgate in the closed position. Another pair of cylinders manage the tailgate opening/closing and avoid potential interferences between the two functions and tension loss to the belts.

Bale density is easily set from the baler hydraulic valve, a simple but efficient solution for operators not changing hydraulic settings several time in a day. Bale density can be controlled from the cab thanks to a hydraulic gauge on the front of the baler.

To optimize harvested hay quality, a softcore is offered as standard, which removes hydraulic pressure. This function can be adjusted (from 1-m [3.3-ft] bale diameter) and activated from cab no matter the monitor choice. By providing a loose bale core, softcore function is particularly helpful when baling hay that has residual moisture or when unrolling bale by hand.

Bale chamber design optimizes machine versatility

Three bale chamber rolls facilitate bale rotation

Three bale chamber rolls facilitate bale rotation  Laced belts can be changed or repaired quickly and for limited cost

Laced belts can be changed or repaired quickly and for limited cost The bale chamber on the V451G Baler features a starter roll and two front rolls, all driven, to allow a quick crop rotation, whether harvesting short silage or brittle crops.

Easy bale starting, facilitated by the three rolls, avoids aggressive belt patterns that often cause crop accumulations. The six belts – derived from traditional diamond John Deere belts - keep the three plies but adopt a smooth pattern.

Belts are powered by a single big-diameter rubber roll. A second driven roll is available as an attachment for extreme conditions.

The belts are all joined thanks to proven and durable MATO® type lacers. Belts can be easily removed and repaired, something not possible with an endless belt design.

Due to initial empty bale chamber geometry, round bales created by the V451G Baler feature a star-shaped core comparable to the one offered by fixed chamber balers. This star shape guarantees easy bale unrolling, no matter the density settings.

MATO is a trademark of MATO GmbH & Co.

Displays provide comfortable operator experience

Optimize the display depending on real needs

The V451G Round Baler can be delivered with two different displays, both from the BaleTrak™ monitor family.

BaleTrak Easy monitor manages essential functions

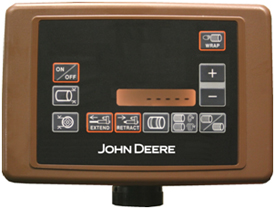

BaleTrak Easy monitor

BaleTrak Easy monitor The BaleTrak Easy monitor has been specially designed for small and medium farms and is focused on the following essential functions:

- On and off

- Bale diameter setting

- Softcore activation and diameter setting

- Net system settings (number of turns, tying delay)

- Manual net wrapping process launch

- Manual net system actuating

The liquid-crystal display (LCD) offers complementary information such as:

- Current bale size

- Tying status

- Total bale count

- Resettable bale count

BaleTrak Easy is not compatible with net plus twine-tying option. BaleTrak Easy can only be ordered with net-only option. As a member of the BaleTrak system range, the BaleTrak Easy offers expected reliability, allowing longer usage life.

BaleTrak monitor fits demanding operator expectations

Advanced settings and information on BaleTrak display

Advanced settings and information on BaleTrak display The BaleTrak display is offered as an option on the V451G Baler. The monitor provides the same functions as the BaleTrak Easy, plus additional settings and information:

- Electronic bale shape status (no bale shape indication, even mechanical on the baler with BaleTrak Easy)

- Twine system management capability, including independent right/left space from twine end to bale edge and twine feeding monitoring

- Full icon description, such as gate status, tying mode, tying status, bale status, battery status, and stop alarm

- Five resettable bale counters

- Total hours counter

- Four factory presets for the wrapping cycle, plus one customizable

The BaleTrak display is mandatory when choosing the net and twine binding option.

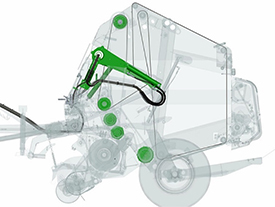

Simple driveline gives durability and peace of mind

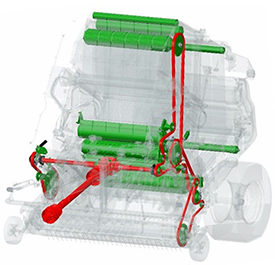

Driveline design of baler

Driveline design of baler As with each John Deere round baler, simplicity has been a key driver in V451G Series Balers development. Open a shielding – no matter the side – and see the clear and clean driveline design that guarantees long lifetime and low maintenance.

Low number of chains reduces risk of trouble

Only four chains to drive the full baler

Only four chains to drive the full baler The V451G driveline has been designed to limit maintenance, which is often linked to long life. Only four chains are necessary to drive the complete baler:

- One chain for pickup drive

- One chain for rotor drive

- One chain for upper front roller and for belts rubber roll

- One chain for starter roll and front rolls

All chains (except pickup) are RC80 size, 25.4 mm (1 in.), and feature high-tensile resistance and long life.

This extreme design simplicity teamed with high-quality components match the most demanding small and mid-size farm expectations.

Oversized components guarantee long life and safe ride

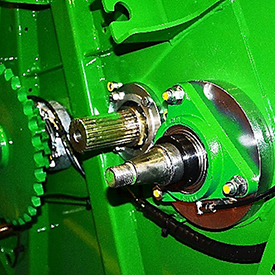

Greaseable 50-mm (2-in.) double-row roller bearings assembled on the V451G

Greaseable 50-mm (2-in.) double-row roller bearings assembled on the V451G  Greaseable bearings are on all critical rolls

Greaseable bearings are on all critical rolls To provide the expected long life and quiet ride most demanding users are waiting for, the V451G implements oversized bearings:

- On the left-hand side, 50-mm (2-in.) double-row greaseable roller bearings can be seen.

- On both sides, close to 50 percent of the rolls are handled by double greaseable bearings (two bearings side-to-side). Doubling bearings allow increased load capacity by up to 40 percent versus traditional single-bearing/single-ball row concept.

- All key bearings are greased (grease bank as standard for all bearings requiring daily greasing), giving long life to the components.

- All bearings are protected by a sealing concept inspired by high-spec fixed chamber baler components to keep aggressive silage juice and dust from polluting the bearing. The sealing is a key parameter to extending bearing lifespan.

T-shaped gearbox balances load on both sides of the baler

T-shaped gearbox shares the load between the feeding system and bale chamber

T-shaped gearbox shares the load between the feeding system and bale chamber The entry-level baler in the John Deere variable chamber baler range, the V451G features a T-shaped, three-pinion gearbox often only found on high-spec balers. This T-shaped gearbox shares the power between the feeding system (right baler side) and the bale chamber (left baler side) independently. Compared to a traditional L-shaped gearbox that transmits all load to a single machine side or to a T-shaped gearbox with only two pinions, the John Deere design reduces baler frame stress and provides longer life.

Both gearbox outputs are directly linked to straight coupling sleeves that are only required to be greased twice a year.