E260-II

Mid-Size Excavator

- Net Power: 143 kW (192 hp)

- Max Digging Depth: 7.16 m (23 ft. 6 in.)

- Operating Weight: 26,300 kg (57,982 lb.)

Features

Enjoy all day comfort in our spacious and ergonomically friendly cab

E260LC cab external view

E260LC cab external view To maximize the productivity and comfort, we have loaded the cab with lots of operator-friendly features to keep them satisfied throughout the entire day.

- The size of the cab is the first thing that catches the customer eye. It offers generous legroom and benefits large area behind the seat for extra onboard storage space. It is also one of the few cabs in the industry, which allows the seat to be reclined into a comfortable resting position.

- New automotive-quality styling and exceptional materials provide a superior feel and look of a truly premium piece of equipment.

- Increased glazing area of the right window as well as lean and effective component placement inside of the cab supports advanced all-around visibility.

- Bright and easy-to-read 17.8-cm (7-in.) touch screen monitor provides quick access to a wealth of machine data and multiple functions.

- Cab is pressurized to minimize dust and dirt intrusion during operation. It is also equipped with a very efficient A\C system, that maintains the desired cab temperature throughout the day.

- The majority of machine controls are located on the Sealed Switch Module (SSM) to the right from operator, improving general ergonomics in cab and logically combining all functions in one area.

- Optional air ride seat, included in the Premium cab option, provides even more comfort to operators, reducing their fatigue during long shifts. It also includes the incline adjustment of the lower part of the seat, which is very helpful for machines working on slopes.

SSM panel

SSM panel  Main touchscreen

Main touchscreen Lower your overheads with impressive fuel efficiency and other cost-saving features

Meet one of our most versatile excavators

Excavator in truck loading application

Excavator in truck loading application Looking for a versatile, strong and efficient excavator, that can be both involved in civil works and at the same time support the gravel or sand quarry operations? Meet our E260LC – one of most universal Deere excavators. It is built to be strong and productive around John Deere Intelligent Hydraulic Control (JD-IHC) system, that ensures efficient synergy of Deere 6068 engine and progressive hydraulic pumps to deliver fast response and advanced precision of controls. The integration through common software infrastructure delivers superb hydraulic tuning, for faster digging cycle even trough hard or packed material. E260LC is a 20-tonn class machine, that for some applications can be equally efficient to 30-tonn one.

- Field-proven Deere 6068 engine delivers confident power levels at 143 kWt Net. One of the highest arm digging forces in the size class – 134 kN – combined with solid bucket force - 176 kN – allows the machine to be a high performer in any earthmoving, general construction or even quarry applications.

- Ability to offer the 1.5 m3 heavy duty (HD) bucket for materials with density at 1800 kg\m3 allows to utilize the E260LC even on sand or rock quarries for efficient truck loading.

- An extra bottom roller (ten in total vs. nine on competitor machines) better distributes the weight and improves the stability and ride across uneven terrains.

- The pressure boost feature is now automatic, creating a seamless experience for the operator. It activates for 8 seconds, when extra impulse is required to overcome the heavy soil layer or move heavy load.

- Improved controllability and machine cycle times achieved by utilization of new pumps with bigger displacement and newly designed main control valve for advanced precision and controllability.

- Wide selection of buckets and ability to choose between general duty (GD) and heavy duty (HD) booms and arms, allows you to tailor the machine to specific application.

- Four Power Modes (Low, Economy, Standard, and High) easily adapt machine behavior to changing job demands, so you can find the right balance of productivity and fuel economy. Three work modes — Lift, Dig, and Hammer/Bidirectional Auxiliary — allows an operator to choose the proper hydraulic response for specific applications and attachments.

- Variety of hydraulic auxiliary line options expands the versatility and capabilities of the machines. Two-way hydraulic lines, low flow and merge flow options combined with specifically designed payloads make the Deere machine a perfect carrier for various types of attachments.

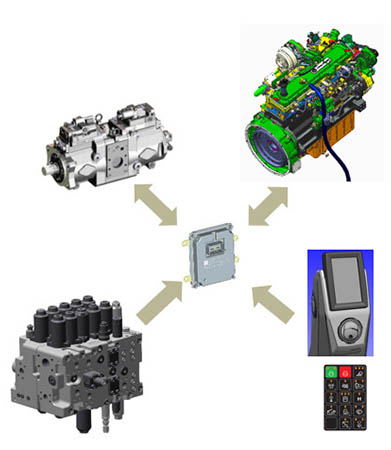

JD-IHC system combines engine, hydraulic pump, control valve and main controllers

JD-IHC system combines engine, hydraulic pump, control valve and main controllers Well-known Deere quality that allows you earn more by minimizing downtime

John Deere excavator in quarry application

John Deere excavator in quarry application Uptime is important to operators, so John Deere put a lot of effort in designing and building dependable machines, that demonstrate high reliability and longevity. Understanding, that an excavator is more than just a “shovel” and users want a versatile and universal tool, thousands of Product Verification And Validation (PV&V) and engineering hours were put into extensive testing of the future design in various conditions. This ensures, that machines can withstand different loads and applications and meet the expectations of the most demanding users.

- Sealed and lubricated undercarriage and heavy-duty welded X-frame provide a solid, stable platform. Sloped track frame resists material buildup to decrease cleaning time.

- Heavy-duty cooling system keeps the engine and hydraulic system running efficiently, even in tough environments. Optional heavy-duty arm and boom are built and designed for long life even in severe applications.

- Reliable John Deere PowerTech™ diesel engines feature replaceable wet-sleeve cylinder liners that resist wear and dissipate heat more evenly, for longer life.

- Solid-state electronics and uncomplicated system architecture minimize the number of wires, mechanical relays, and electrical connectors needed. Streamlined routing for hydraulic hoses boosts reliability while easing repairs.

- To support the long and intensive runs we have designed our cooling system to be extremely efficient even in tough environments.

- Advanced onboard diagnostic system turns the color 17.8-cm (7-in.) display into the powerful service tool, improving the test procedures and providing important data at your fingertips.

- JDLink™ systems allows remote access to important machine data, as well as supports two-way communication between the equipment and Dealer technicians in the office, enabling the remote diagnostics and ability to track parameter changes across time.