r310r

Mower Conditioner

- Outstanding manoeuvrability

- Highly efficient cutterbar

- Better balance

- Conditioning choices

Features

High-performance, low maintenance cost machine for best forage quality

The R310R Rear-Mounted Mower-Conditioner represents the high-spec machine range within the John Deere mounted mower-conditioner portfolio. The machines serve dairy and livestock producers’ demand of high productivity and longer uptime, combined with a low cost of operation.

The R310R has a cutting width of 3.1 m (10.2 ft) and is equipped with a cutterbar which ensures a perfect mowing picture and high forage quality even in difficult harvesting circumstances. The model is available with two conditioner specifications.

The impeller conditioner fits the needs of producers who want to work mainly in grass-dominated forage crops. The roller conditioner provides a gentler conditioning for producers who work mainly in leafy, fragile forage crops like clover or alfalfa. Both conditioning solutions provide versatile adjustment of the conditioning intensity. This versatility offers the possibility to adapt the machines to a wide variety of field and crop conditions.

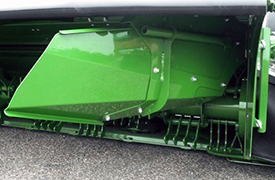

Rotary disc cutterbar for cutting in tough conditions

Cutting bed

Cutting bed The R310R has a cutterbar with 3.1-m (10.2-ft) cutting width. Seven discs and 14 knives are the perfect prerequisites for a high-performance cut.

The cutterbar is mounted in the frame of the machine. This ensures high stability of the machine. Additional shock absorbers on the left and right side improve this stability.

The cutterbar secures excellent mowing quality in all circumstances. The overcutting areas at the discs ensure perfect mowing in wet or sticky crops. This significantly reduces crop accumulation on the discs and time-consuming cleaning of the machine.

Power is transmitted from the 1000-rpm tractor with 44.4-mm (1.75-in.) power take-off (PTO) through a central gearcase to the cutterbar of the rear-mounted mower conditioner.

- Each cutterbar is protected by a slip clutch and overrunning clutch.

- The cutterbar is securely mounted within the frame for strength and durability.

- Power is transmitted to the rotary discs through fully enclosed gears running in oil for quiet, smooth, reliable operation.

- To meet serviceability, the cutting bed is lubricated for life; no oil changes are necessary.

- The high-speed rotary discs cut in the toughest conditions. The discs rotate at 2986 rpm.

- All discs offer an orbital cutting diameter of 440 mm (17.3 in.).

- Low-profile design enables cutting close to the ground at a flat angle, helping to prevent damage to the discs and knives. A constant mowing height is supported.

- Cutting height is adjusted by changing cutting angle via the third point.

- Non-braked knives that rotate at 360 degrees have improved durability.

- Heavy-duty knives for longer durability are also available.

- Pinion gear is easily removed from the top of the cutterbar for service.

- Idler gears can be removed from access area after removal of pinion gear.

Quick Knives Exchange for uptime and best operator comfort

Quick Knives Exchange technology

Quick Knives Exchange technology The Quick Knives Exchange technology is standard for this machine. It has been developed to increase productivity through a significant downtime reduction when changing knives.

The amount of time spent on changing has dropped from three minutes per knife to about 15 seconds. It is an efficient way to save up to 40 minutes of maintenance time on the platform.

The R310R is fitted with seven discs, and every disc has two knives. Operators only need to insert the special tool (attached to the mower-conditioner) between the disc and spring blade, push it down and remove the knife. No parts are lost during the change process.

Operator comfort is even further enhanced since knives used on the Quick Exchange Knives cutterbar are designed to provide nearly the same cutting height as the classic cutterbar from 35 mm to 65 mm (1.4 in. to 2.6 in.). These knives, with a double cutting face, are the only ones to guarantee excellent cutting quality and efficient use with the Quick Exchange Knives cutterbar: there is no crop accumulation and an easy come-back-to-cutting position.

Large farms, machinery rings, and contractors need high-quality output and ease of serviceability:

- The cutterbars are fast mowing, with high-quality work and reliable setup.

- 360-degree rotating knives for best productivity

- Each disc is protected against heavy shocks with a shear point located on the disc drive.

- All modules and intermediate gears are quickly and easily interchangeable.

To meet high-quality output, the cutterbar is an oil-immersed gear-driven cutting bed:

- All discs offer an orbital cutting diameter of 440 mm (17.3 in.).

- With seven discs, the cutting width is 3.1 m (10.2 ft).

- Disc speeds are 2986 rpm.

To meet serviceability, the cutting bed is lubricated for life:

- No oil changes are necessary.

- Discs are fitted with Quick Exchange Knives technology.

- Cutting height is from 35 to 65 mm (1.4 to 2.6 in.).

Impeller conditioner for intensive conditioning and solid swath forming

The impeller conditioner has pre-loaded steel fingers to provide the right impact on the plant to remove the waxy coat.

- The R310R is equipped with four tines in a V-shape and 76 straight tines.

- This accelerates the drying process while requiring only little maintenance.

To improve productivity:

- Five conditioning positions are available with two rotation speeds of 755 or 1000 rpm.

- Speed change is done by a simple selector on the gearbox.

Lever with two positions to simply change conditioning speed

Lever with two positions to simply change conditioning speed The impeller is not designed to condition leguminous plants; however, if it must, choose the light conditioning effect with the 755-rpm rotation speed and the conditioner adjustment lever on the minimum position.

Conditioner adjustment

Conditioner adjustment Proper conditioning in a wide range of crops can be achieved when the conditioner is properly adjusted. Conditioning intensity can be chosen out of five positions.

The desired swath size can be easily obtained with adjustable swath deflectors. For the R310R, sizes from 1.2 m to 2 m (3.9 ft to 6.6 ft) are possible:

- A wide spread is available on all machines when very fast drying is required.

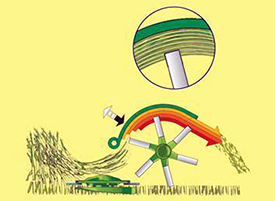

How an impeller conditioner works:

Conditioning effect

Conditioning effect As hay is cut by rotating knives, tines pick up the plants and carry them through the machine. Tines are free swinging to reduce damage to the conditioner if rocks or other solid objects are struck.

As the plant passes through, it rubs against the conditioning hood and other plants. Scuffing action removes the waxy surface from the stem of the plant to allow faster evaporation of moisture.

The pivot point for the conditioning hood is also adjustable to provide a wider range of conditioning intensity.

The speed at which the tines rotate also affects the degree of conditioning.

Two impeller speeds can be achieved by moving the speed selector on the gearbox. High speed provides an efficient conditioning while the lower speed provides a lighter conditioning.

With the selector on the rabbit position, the impeller turns at 1000 rpm. If the selector is on the turtle position, the impeller turns at 755 rpm.

Versatile windrowing solutions to match different harvesting circumstances

The available room for a windrow is a function of wheel spacing and tire width. The windrow width of the R310R can be easily adapted by adjusting the forming shields.

Windrow formation

Adjustable swath deflector

Adjustable swath deflector  Windrow

Windrow Forming shields are easily adjusted to control material flow. This allows the operator to match the windrow width to harvesting requirements

The desired swath width can easily be obtained by loosening the handle on each side and moving the adjustable swath deflectors to the desired position. No tools are required to adjust the forming shields. Swath width is adjustable from 1.2 to 2 m (3.9 to 6.6 ft) for the R310R.

A wide spread is available on all machines when very fast drying is required. The bundle consists of vanes that are installed behind the conditioning hood. The windrow width when using the widespread kit can be adjusted to be approximately the same as the cutting width of the platform.

Windrow forming shields (rear curtain raised for visibility)

Windrow forming shields (rear curtain raised for visibility)  Adjustment handle

Adjustment handle Vertical fold feature for highly maneuverable street transportation

Transport position of the R310R

Transport position of the R310R Producers in small-structured landscapes and narrow field entrances face challenges when they transport their machines.

The R310R Rear-Mounted Mower-Conditioner is the first John Deere single rear-mounted mower-conditioner which has a vertical fold transport position.

Folding up to 120-degrees and a pivoting point close to the tractor allows the best stability on the road.

To bring the machine to its transport position, the operator works with the double-acting selective control valves (SCVs) to move the machine from headland position to transport position. A transport lock ensures maximum safety.