W235M

Windrower

- 235 hp

- Integrated AutoTrac™ steering system helps maintain crop quality even at faster cutting speeds

- JDLink™ enabled

- Optional 38.62 km/h transport speed

Features

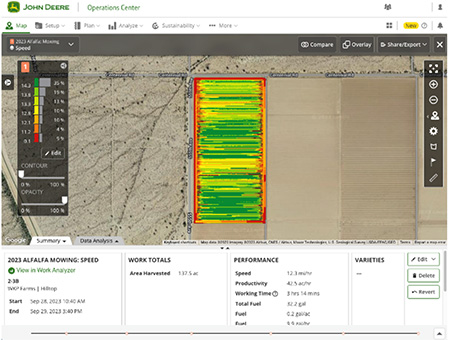

Analyse Mowing Performance with Mowing Documentation in Operations Center™

Monitor in field performance anywhere and anytime with John Deere Operations Center

Monitor in field performance anywhere and anytime with John Deere Operations Center  Field Analyzer

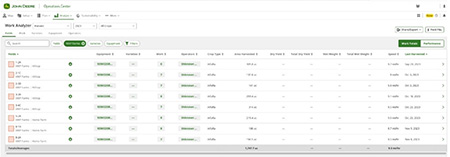

Field Analyzer  Work Analyzer

Work Analyzer NOTE: Mowing and Swathing used interchangeably.

Overview

In the John Deere Operations Center, Mowing Documentation equips operators with the tools they need to make informed decisions anytime and anywhere by providing comprehensive insights into in-field performance. This capability enables operators to monitor and track key metrics such as speed, productivity, working hours, and fuel efficiency for each machine and field.

Benefits

Optimise Your Mowing Schedule: Leverage the cut date history feature to identify which fields are due for mowing next. By reviewing previous cut dates, operators can efficiently plan upcoming mowing schedules. This information can be seamlessly sent to the operator’s display through a Work Planner file, ensuring timely and organised operations.

Evaluate Dry Down Times: Combine Mowing Documentation with Bale Documentation to assess dry down times effectively. By analysing the days between mowing and baling, operators can optimise their processes and enhance the quality of their yield.

Identify Efficiency Opportunities: Use the data provided by Mowing Documentation to uncover efficiency opportunities at both the machine and operator levels. Evaluate metrics such as speed, productivity, fuel consumption per area, and fuel rate per hour. Coverage maps and seasonal performance reports available in Work Analyzer will help you gain a clearer understanding of field performance and identify areas for improvement.

Seamless Data Integration with JDLink™: With JDLink, the transfer of machine and agronomic data between your equipment and the Operations Center is seamless. This integration enhances monitoring, planning, logistics, and analysis, making it easier for operators to manage their tasks and optimise performance.

Effectively monitoring operator performance: Essential for maximising field efficiency and ensuring a positive work environment. By tracking individual machine performance, managers can gain valuable insights into each operator’s strengths and areas for improvement. This data-driven approach allows for strategic adjustments, including the reassignment of operators to different functions when necessary to improve equipment efficiency and employee satisfaction.

Additional details

By utilising Mowing Documentation and its associated tools, John Deere operators can enhance their efficiency, streamline their workflows, and make data-driven decisions that lead to improved outcomes in the field.

Comfort and productivity with M- and R-spec cab features

In-Cab Comfort: Enhancing Operator Experience

Operators spend long hours in Self-Propelled Windrowers while mowing and forming windrows, making cab comfort essential for reducing fatigue and maintaining productivity throughout the day. A well-designed cab can significantly enhance the operator's experience, allowing them to focus on their tasks without the distractions of discomfort.

In-Cab Productivity: A Focused Working Environment

The Self-Propelled Windrower cab is engineered to maximise productivity. It features a quiet working environment, providing operators with the peace they need to concentrate. With ample visibility, operators can easily monitor their surroundings and make quick adjustments as necessary. Additionally, the cab is equipped with thoughtful storage solutions and user-friendly features that facilitate efficient work processes.

Both M and R Spec cabs provide rear camera options for all models, along with merger camera options specifically available for the W235M, W235R, W260M, and W260R windrower models ordered merger ready from the factory.

Compatibility: Tailored Options for Every Operator

John Deere offers Self-Propelled Windrowers with two distinct cab options: M-Spec and R-Spec. Each cab type is designed to cater to different operator preferences, offering unique in-cab features, advanced seat suspensions, and a variety of conveniences. The exterior cab designs are also tailored to enhance functionality and style, ensuring that operators not only feel comfortable but also have the tools they need for a successful day in the field.

By prioritising in-cab comfort and productivity, John Deere Self-Propelled Windrowers provide operators with the ideal environment to perform at their best, reducing fatigue and maximising efficiency on every job.

| M-Spec | W200M, W235M, W260M |

| R-Spec | W235R, W260R |

M-spec cab

M-spec windrower cab interior

M-spec windrower cab interior  M-spec windrower cab exterior

M-spec windrower cab exterior Select | ||

Comfort and Convenience | Seat |

|

Infotainment |

| |

Interior upholstery | Upholstery without right- hand storage | |

Exterior styling | Without exterior styling panels | |

Visibility | Lighting | Halogen |

Mirrors | Manual | |

Sunshades | Front | |

Wipers | Front | |

Seat suspension | Air (passive) | Yes |

Active suspension | No | |

Precision Ag Technology | Integrated StarFire™ receiver | Integrated StarFire Ready |

Display | 25.7 cm (10.1 in.) G5 CommandCenter™ with the Cornerpost display | |

Extended Display | No | |

R-spec cab

R-spec windrower Ultimate cab interior

R-spec windrower Ultimate cab interior  R-spec windrower cab exterior

R-spec windrower cab exterior The R-spec cab comes in three different trim levels:

Premium cab with air suspension seat

Ultimate cab with air suspension

Ultimate cab with air active seat

| Premium with air suspension (Base) | Ultimate Cab with air suspension (Option) | Ultimate Cab with Active seat (Option) | |

Comfort and Convenience | Seat |

|

|

|

Infotainment |

|

|

| |

Interior upholstery | Upholstery without right-hand storage | Upholstery with right-hand storage | Upholstery with right-hand storage | |

Exterior styling | With exterior styling panels | With exterior styling panels | With exterior styling panels | |

Visibility | Lighting | LED | LED | LED |

Mirrors | Electric heated | Electric heated | Electric heated | |

Sunshades | Front/rear | Front/rear | Front/rear | |

Wipers | Front | Front | Front | |

Seat suspension | Air (passive) | No | No | No |

Active suspension | Yes | No | Yes | |

Precision Ag Technology | Integrated StarFire™ receiver | Integrated StarFire ready | With Integrated StarFire | With Integrated StarFire |

Display | 32.5 cm (12.8 in.) G5Plus CommandCenter with the cornerpost display | 32.5 cm (12.8 in.) G5Plus CommandCenter with the cornerpost display | 32.5 cm (12.8 in.) G5Plus CommandCenter with the cornerpost display | |

Extended display | Yes | Yes | Yes | |

Bluetooth is a trademark of Bluetooth SIG, Inc.

Automated temperature control - M- and R-spec

Select comfort and convenience package for M spec windrowers

M Spec windrowers

The select comfort and convenience package is available for the M spec windrowers.

Cloth seat

Cloth seat Cloth seat

- Improved swivel seat – 16 degrees to the right

- Air ride suspension

- Mechanical adjustment controls

- Mechanical lumbar support

Heated and cooled floor ventilation

- Floor vents located directly behind the operator’s feet improves airflow heating during cold mornings or cooling throughout warm days

CommandARM™ console

- Tablet mount holder integrated into the CommandARM rail

Plenty of storage

- Three cup holders

- Easily accessible storage compartments located to the right and behind the seat

Precise control of the machine with the CommandARM™ console

CommandARM console in the W200M Windrowers

CommandARM console in the W200M Windrowers  CommandARM console in the W200R Windrowers

CommandARM console in the W200R Windrowers Overview

The CommandARM console provides the operator with unmatched control of the windrower and platform. The whole functionality of the windrower can be controlled from one place. Controls are designed and positioned with ergonomics designed controls for easy access and usability.

Benefits

- Similar design used in John Deere tractors and combines, making it easy to use with a consistent layout.

- Usability and convenience are increased through ergonomics and button layout.

- Operator preferences realised through customisable independent fore/aft and height adjustment preferences.

- No need to move from the CommandARM.

- CommandARM developed to harmonise perfectly with CommandCenter™ display controls and multifunction control lever.

Additional details

Designed with operator comfort in mind, the CommandArm console can be adjusted in multiple ways – at an angle, fore/aft, and up and down for precise operator use and comfort. The CommandARM console provides access to the most frequently used windrower controls:

- Field/road speed range

- Float adjust

- Platform speed adjustments

- Throttle – low idle, variable idle, and high idle

- Platform engage/disengage

- TouchSet™ platform adjustments

- Windrower merger speed, raise, and lower (if equipped)

- Road hazard engage/disengage

- G5 and G5Plus CommandCenter™ displays navigation

- Display menu shortcut buttons

- Climate control switches

- Worklight switches

- Beacon light switches

Multi-function lever

Multi-function lever

Multi-function lever Benefits

The controls vital to the operation of the W200 Series Windrowers are conveniently located on the multi-function lever. The ergonomic multi-function lever gives the operator fingertip control of the following functions:

- Platform float suspension adjustment

- Windrower merger position, angle, and speed (if equipped)

- Platform presets (to raise, lower, and engage AutoTrac™ system)

- Increase/decrease cutterbar or draper speed

- Platform raise/lower

- Platform tilt

The multi-function lever is also associated with the following functions:

- Forward/reverse ground speed

- Automatically disengages the park brake when moved from the park position with the engine running

- The park brake is automatically engaged when placed in park.

- With platform enabled and on rotary traction units only, automatically raises the platform when moved from forward to reverse position

- This function prevents wrapping cut crop into condition rolls.

Additional details

The multi-function lever is linked to key operational features:

- Forward/Reverse Ground Speed Control: Seamlessly switch between forward and reverse speeds.

- Automatic Park Brake Disengagement: The park brake automatically disengages when the lever is moved from the park position with the engine running.

- Automatic Park Brake Engagement: The park brake engages automatically when placed in park.

- Platform Automatic Raise: On rotary traction units, the platform raises automatically when moving from forward to reverse, helping to prevent wrapping cut crop into condition rolls.

With the CommandARM console and multi-function lever, operators of the W200 Series Windrowers can enjoy a blend of comfort, control, and efficiency, allowing them to focus on achieving optimal performance in the field.

Easy-to-use G5 and G5Plus CommandCenter™ Displays

G5Plus CommandCenter

G5Plus CommandCenter The G5Plus CommandCenter is the new central information system used on all Windrowers. The G5 CommandCenter will be used on M spec machines, while the G5Plus Command Center will be for the R spec windrowers, in both trim levels. The R spec windrowers also feature an optional G5Plus extended monitor, available to order for improved in field performance. The G5Plus display allows the operator to view various important harvest and diagnostic information during harvesting and organised in a layout based on operator preferences. The G5Plus CommandCenter has been developed in combination with the CommandARM™ console and the multifunction control lever to deliver outstanding ergonomics paired with best-in-class natural navigation.

Benefits

- Display is easy to use due to its commonality across John Deere agriculture products

- Large area for information provided by a 32.5-cm (12.8-in.) screen

- Quick and easy navigation with touch functionality similar to Gen4 displays

- 10 percent less button presses compared to the previous design because of app-based interface

- Easy, logical, and intuitive operation with five run pages which can be customised by the operator

- Improved uptime due to display interface time savings, including shortcut keys below the display that allow access to the most important combine functions

- To increase the digital display area, an G5Plus Extended Monitor is available for the R spec windrowers only.

Additional details

Five run pages can be configured by the operator according to their preferences for easy, logical, and intuitive operation. By scrolling to the left and right on the display, the operator can conveniently switch from run page to run page just like on a smartphone. In addition, the operator can switch the run pages from the multifunction control lever. This means the operator does not have to move their hand off the controls but is still able to navigate through run pages.

Quickly see important information on the cornerpost display

Cornerpost display

Cornerpost display Overview

The corner post display will be equipped from the factory, mounted in-cab onto the right-hand cornerpost. The cornerpost display shares live windrower information to the operator all from a single view. This display is positioned such that the operator can obtain this important information while maintaining heads-up focus of what’s ahead of the windrower. Its design allows optimum viewing of the header around the display with no obstruction.

Benefits

The cornerpost display is divided into an upper and lower region. The upper region provides traction unit information, and the lower region provides platform specific information.

- Traction unit information- ground speed, engine revolutions per minute, engine coolant temperature gauge, fuel level gauge, DEF level gauge, engine power meter indicator, high beam indicator, high exhaust system indicator, and right and left turn signal indicators.

- Header positioning information- Header speed display, and float pressure display

NOTE: The display does not have touchscreen capability for Windrowers

Control engine oil and temperatures with efficient cooling packages

Radiator screen assembly

Radiator screen assembly The W200 Series Self-Propelled Windrowers feature several improvements over previous designs to keep the engine operating at optimal levels and improve engine life. Design features include:

- Increased screen area of 19 percent provides more air flow through the cooling package than previous models.

- Smooth, rounded path inside the wand and ducts keeps debris from slowing and plugging.

- Air lab engineered and field-tested ducting is sized for air velocity and continual removal of debris.

- Wand backer plate helps stop debris from being sucked against the screen from the cooling fan for better cleaning performance.

- Cool air intake draws air from above the chassis, minimising debris intake to cooling package.

- A stamped metal rear screen provides easier cleaning.

- The air conditioner condenser and oil cooler assembly swing out for easy serviceability and cleaning.

Oil cooler and air conditioner assembly

Oil cooler and air conditioner assembly The W200 Series Windrowers are tested in tough conditions of over 37.8° C (100° F) to ensure that the drives stay properly cooled for maximum life and reliability. The 94.6-L (25-gal.) oil reservoir supplies oil to the pumps. Oil is cooled as it passes through the combination oil cooler and air conditioner condenser assembly at the rear of the machine.

Live monitoring of the hydraulic oil temperature at the left and right drive motors and reservoir limit switch protects against overheating during drive motor stall or high-grade terrain conditions

Variable-speed fan drive

Variable-speed fan drive The eight-blade cooling fan incorporates a viscous drive system that provides precise control over fan speed during operation. Optimisation of the viscous fan speed leads to significant reductions in parasitic losses in certain operating conditions.

The fan speed is controlled by various factors such as engine coolant temperature, intake manifold air temperature, or hydraulic oil temperature. This level of control allows the fan to operate only at the required speed to keep the engine and cooling package at optimal operating temperature and reduces engine noise levels.

Dependable operation with heavy-duty drive motors

Heavy-duty drive motor

Heavy-duty drive motor The heavy-duty drive motors are engineered to deliver an enhanced torque rating, ensuring reliable operation across a variety of challenging conditions, including field borders, irrigation wheel tracks, and rough terrain.

- M-spec machines, customers can choose between two speed options: 29 km/h (18 mph) and 38.6 km/h (24 mph).

- R-spec machines are exclusively offered at a speed of 38.6 km/h (24 mph), providing consistent performance tailored for demanding agricultural tasks.

Easily fuel the windrower from the ground

Fuel and diesel exhaust fluid tanks

Fuel and diesel exhaust fluid tanks The W200 Series Self-Propelled Windrowers are equipped with strategically positioned diesel fuel and diesel exhaust fluid (DEF) fill locations, offering unparalleled convenience for ground-level refuelling. This design not only streamlines the refuelling process but also enhances operational efficiency, ensuring that operators can quickly and easily maintain their machines, allowing them to focus on what truly matters—maximising productivity in the field.

DEF sight gauge

DEF sight gauge The DEF sight gauge is a valuable feature that helps operators avoid overfilling the tank, thereby preventing spills and mitigating the risk of damage caused by freezing and expansion in cold weather conditions. This design enhances operational safety and protects the integrity of the system, ensuring reliable performance even in challenging environments.

Remote battery terminal

Remote battery terminal A remote batter terminal, conveniently located on the left-hand platform near the fluid fill, provides power for the 12-V fuel pumps on refuelling tanks.

A conveniently positioned remote battery terminal on the left-hand platform, near the fluid fill area, delivers reliable power for the 12-V fuel pumps used with refuelling tanks. This convenience enhances accessibility and efficiency during the refuelling process, ensuring operators can easily connect and power the pumps as needed.

Consistent cutting and windrow formation with constant header speed

Constant header speed

Constant header speed Overview

The W200 Series Self-Propelled Windrowers feature a unique constant header speed capability, enabled by an advanced hydraulic pump control system. This system continuously monitors platform speed and adjusts the pump’s output to maintain the desired header speed. As a result, operators experience consistent cut quality and uniform windrow formation, regardless of varying crop conditions or changes in terrain.

When crop conditions cause the header to slow down or when the engine experiences increased load due to terrain variations, the control system intelligently redirects additional oil flow to the platform drive motor. This proactive adjustment ensures that the header speed remains at the set point, effectively broadening the peak power range and delivering optimal performance when it is needed most.

Benefits

- Enhanced Fuel Efficiency: The ability to operate the header at slower speeds in lighter crops reduces overall fuel consumption, making it a more economical choice for farmers.

- Optimal Engine Performance: The system allows the engine to run below its rated RPM while still maintaining the set header speed, contributing to improved fuel efficiency and reduced wear.

- Increased Component Longevity: The improved ramp-up and ramp-down speeds during starting and stopping of the platform enhance the longevity of the header and platform drivetrain components, ultimately reducing maintenance costs.

Additional details

The constant header speed feature of the W200 Series Windrowers not only improves cutting efficiency but also optimises fuel usage and extends the lifespan of critical components, making it an invaluable asset for modern agricultural operations.

Smoother ride and better control with IntelliAxle™ steer assist

Maximising efficiency and minimising operator fatigue are crucial for achieving optimal results. John Deere's IntelliAxle Steer Assist, combined with the industry-exclusive rear-wheel steer assist system, provides operator to have more control of the windrower, enabling cutting and transport speeds.

IntelliAxle Steer Assist utilises advanced algorithms to automatically adjust steering sensitivity based on speed and load conditions. This means that as the vehicle moves faster, the steering becomes more responsive, allowing for precise manoeuvring in tight spaces. Conversely, at slower speeds, the steering is optimised for greater control and stability. The IntelliAxle Steer Assist system also has independent rear suspension, which effectively absorbs shocks from the roughest field and road conditions. This design enhances ride comfort and significantly reduces operator fatigue during long hours of work in the field.

Independent rear suspension

Independent rear suspension

Independent rear suspension The independent rear suspension provides smoother steering inputs and reduces the effort required by the operator. The independent rear suspension further contributes to a superior ride quality, absorbing shocks from rough fields and creating a more comfortable ride experience and less operator fatigue during long working hours. Its torsion axle design effectively absorbs shocks encountered in rough terrain, enabling faster cutting speeds and improving overall performance.

Rear-wheel steer assist

Rear-wheel steer assist

Rear-wheel steer assist The rear-wheel steer assist system enhances manoeuvrability both in the field and during transport, offering operators a more responsive and precise handling experience. The W200 Series incorporates an electrohydraulic, proportionally controlled rear steering system that delivers tighter steering and improved control at higher speeds.

This axle design enables in-field working speeds of up to 27.3 km/h (17 mph) and transport speeds of up to 38.6 km/h (24 mph).

The smooth, fluid steering allows operators to maintain complete control of the windrower, particularly during sharp turns and challenging field conditions. Operators can easily adjust the steering sensitivity through the CommandCenter™ display, tailoring it to their personal preferences and the specific demands of the field.

The steer assist system offers three distinct modes of steering assistance based on the machine's speed:

- Inactive Mode: Below 6.4 km/h (4 mph), the IntelliAxle steer assist system is disabled, with steering controlled solely by the front drive wheels.

- Field Range Mode: Once speeds exceed 6.4 km/h (4 mph), the IntelliAxle system activates, providing hydraulic assistance to the rear caster wheels. Operators can set their preferred sensitivity for this mode directly via the CommandCenter display.

- Transport Range Mode: In this mode, operators can independently adjust the steering sensitivity for transport, allowing for optimal control at higher speeds and providing additional flexibility.

This comprehensive steering system enhances the overall performance of the W200 Series, ensuring that operators can navigate their environments with ease and confidence.

Rear steering

Rear steering - Range 1 Aggressiveness (B): Allows the operator to change the aggressiveness of the rear steering when range 1 is engaged. Use range 1 for low speed or field operation.

- Range 2 Aggressiveness (C): Allows the operator to change the aggressiveness of the rear steering when range 2 is engaged. Use range 2 for high speed or transport operation.

Faster field and transport speeds

Faster field and transport speeds are achieved with the increased controllability and stability provided by the rear-wheel steer assist system and independent rear-wheel suspension. The IntelliAxle system, when coupled with the integrated AutoTrac™ steering system, delivers unmatched performance and productivity.

The combination of the rear-wheel steer assist system and independent rear-wheel suspension enables faster field and transport speeds, significantly enhancing controllability and stability. When integrated with the IntelliAxle system and AutoTrac steering technology, it allows operators to navigate their tasks with greater efficiency, ensuring optimal results in both fieldwork and transportation. By also using AutoTrac it allows for accurate guidance and alignment in rows, ensuring optimal cutting performance while reducing overlap and missed areas.

Maximise productivity with integrated AutoTrac™ assisted steering system

W260M Windrower with R500 Rotary Platform

W260M Windrower with R500 Rotary Platform Overview

The W200 Series Self-Propelled Windrowers are equipped with AutoTrac™ technology, an advanced assisted steering system that allows operators to take their hands off the steering wheel as the machine follows the designated guidance line in the field. This feature optimises field operations, enhancing productivity while significantly reducing operator fatigue.

Although operators still need to turn the machine at the end of each row, they can easily resume AutoTrac control by pressing the resume button, allowing the system to steer the windrower down the adjacent pass. The accuracy and controllability of AutoTrac enable faster operating speeds, with the W200 Series capable of reaching up to 27.4 km/h (17 mph) under suitable conditions.

The system employs a unique hydraulic over mechanical design for coarse adjustments to the drive pumps, while an electrohydraulic proportional rear steering system handles fine adjustments. This combination delivers the most precise steering system in its class.

W200 Series Self-Propelled Windrowers come factory-equipped to be AutoTrac ready, requiring only a display, AutoTrac activation, and a StarFire™ receiver to enable the system. Click here to learn more about the necessary components for AutoTrac on W200 Windrowers.

By ensuring consistent engagement of the platform with the crop, AutoTrac contributes to increased productivity, providing more uniform windrows, extending operating hours, and reducing operator fatigue. The integrated AutoTrac system on the W200 Series significantly outperforms previous windrower options, enabling faster cutting speeds and allowing operators to cover more acres in less time.

Benefits

- Maximised Productivity: The combination of automated steering and precision guidance allows operators to cover more ground in less time, optimising their cutting operation.

- Improved Yield: Reduce crop damage and enhance management practices contribute to better yield outcomes.

- Enhanced User Experience: The intuitive interface and customisable settings of AutoTrac make it user-friendly, allowing operators to easily adapt the system to their needs.

Improved cut quality with independent platform float suspension

Increase cut quality on uneven cutting surfaces

Increase cut quality on uneven cutting surfaces Cutting in challenging conditions, such as uneven irrigation berms and pivot wheel tracks, can significantly impact cut quality. The W200 Series Windrowers are equipped with an innovative independent platform float suspension system designed specifically to tackle these obstacles and enhance overall performance. The independent float suspension provides exceptional adaptability, allowing the platform to maintain optimal contact with the ground while navigating uneven terrain. This feature ensures that the windrower can effectively ride on raised surfaces with proper flotation, minimising the risk of gouging and dirt accumulation. By allowing each side of the platform to adjust independently, the float suspension significantly improves cutting quality along irrigation berms and pivot tracks. This adaptability reduces the likelihood of dirt buildup on the platform, which can lead to increased downtime and contamination of the windrow.

Benefits

- The independent float suspension delivers improved cut quality along irrigation berms and pivot

- Improved flotation on non-level surfaces

- Less dirt accumulation, which results in higher quality hay and forage

- Minimised the amount of foreign material mixed in with the cut crop

Quickly adjust rotary header settings with TouchSet™ technology

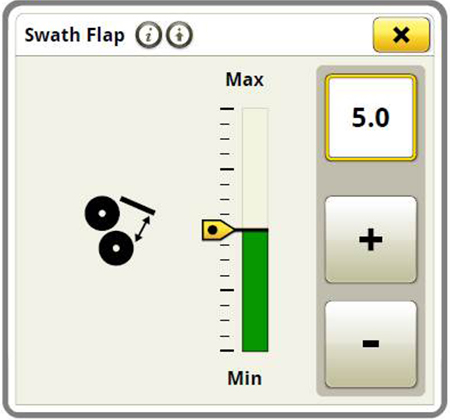

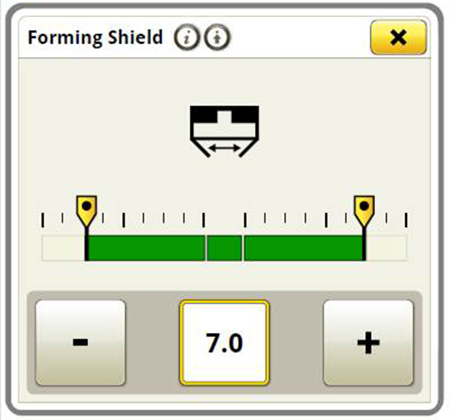

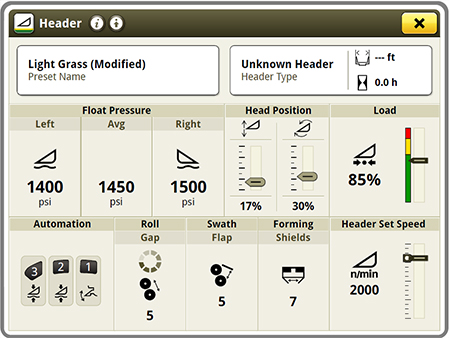

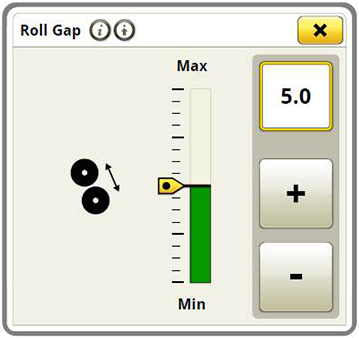

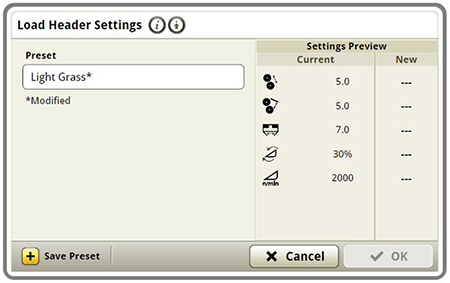

John Deere's TouchSet™ technology enhances the user experience and operational efficiency of their windrowers. This technology provides operators with intuitive control over key R500 platform settings, allowing for quick adjustments and improved productivity in the field. The operator is able to easily adjust and control various settings, like formation shields, roll gap, and swath flap on the go from within the cab, enabling precise management of the machine's performance.

TouchSet is only available with the R500 rotary header.

Quick and precise adjustments

With TouchSet, operators can make real-time adjustments to critical parameters such as cutting height, platform tilt, and other operational settings. This capability ensures that the machine can swiftly adapt to changing field conditions, optimising performance and cut quality. Previously, to perform windrow width adjustments, the operator had to crawl under the machine to loosen and adjust the forming shields.

Adjust the swath flap from the display

Adjust the swath flap from the display  Adjust the forming shield from the display

Adjust the forming shield from the display  Customise a preset for a field or crop

Customise a preset for a field or crop  Roll gap adjustments

Roll gap adjustments  Customise a preset for a field or crop

Customise a preset for a field or crop Preset adjustments

TouchSet includes a preset library for various crops, allowing users to choose the appropriate crop type while cutting. This selection automatically adjusts the header to suit the specific crop. Additionally, operators have the option to create custom presets tailored to a particular field or cutting task. This feature enables quick adjustments to the swath flap, forming shields, head tilt, roll gap, and cutterbar speed.

Benefits

- Improved Operator Comfort: TouchSet technology reduces the complexity of machine controls, making it easier for operators to manage their equipment comfortably and efficiently.

- Consistency in Performance: Quick adjustments lead to more consistent performance across varying field conditions, ensuring high-quality cutting and windrow formation.

- Reduced Downtime: The ability to quickly and accurately adjust settings minimises downtime, allowing for continuous operation and increased productivity during critical harvesting periods.